Hello! I’m Helen. If we haven’t met yet, I’ve spent the last decade navigating the complex world of commercial sanitary ware, helping hotel developers and procurement managers globally turn blueprints into luxury guest experiences.

In my ten years of experience, I’ve noticed a frustrating pattern. A hotel project reaches the 90% completion mark, the rooms look stunning, and then—tragedy strikes. A leak appears on the ceiling of the lobby, or a guest in a newly opened suite complains that their bathwater won’t drain.

Expert Insight: What causes hotel bathtub installation problems?

Hotel bathtub installation problems are usually caused by poor pre-installation planning, not on-site workmanship. Most leaks, drainage failures, and rework can be avoided by confirming dimensions, load, drainage, and waterproofing responsibilities before installation.

Table of Contents

Why Is Hotel Bathtub Installation a High-Risk Stage in Commercial Projects?

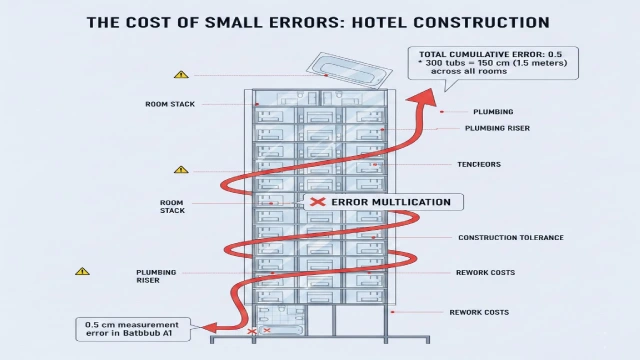

In a residential setting, a single bathtub installation error is a headache. In a 300-room hotel, it’s a catastrophe. From my perspective, this stage is a high-risk node for three specific reasons:

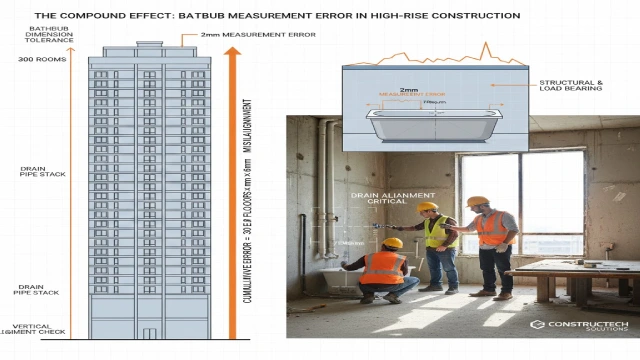

The Multiplier Effect: Any minor measurement error is magnified by hundreds of units. If the drain is off by 2cm, it’s off in every room on that vertical stack.

High-Frequency Stress: Hotel tubs endure 300+ users a year and aggressive daily chemical cleaning. Unlike a home tub, the hotel bathtub installation must withstand industrial-level wear and tear.

The Responsibility Gap: With plumbers, tilers, and waterproofers all working in the same square meter, the responsibility for a failure becomes blurred.

Hotel bathtub installation is the point where the risk concentrates, but the root of that risk usually lies in the planning phase before a single tool is touched.

Source: Overcoming common challenges in commercial shower construction

What Are the Most Common Hotel Bathtub Installation Mistakes? (And How to Avoid Them)

Based on the hundreds of projects I’ve supervised, here are the eight critical errors that drive up your bathtub installation cost and how you can prevent them.

1. Confirming Dimensions Only After Rough-In in Hotel Projects

Confirming bathtub dimensions only after plumbing rough-in is one of the most common causes of drainage misalignment in hotel projects.

I once saw a project in Southeast Asia where the rough-in plumbing was completed based on a “standard” size, but the actual tubs arrived 2cm wider. The result? Every single drain was misaligned, leading to weeks of expensive pipe relocation and delayed handovers.

How to Prevent It: Lock in your dimensions during the design phase. Demand a final technical drawing from your supplier and cross-reference it with the site’s CAD files.

2. Failing to Assess Structural Load in Commercial Hotel Bathrooms

Inadequate assessment of the bathtub’s weight and floor load-bearing capacity often leads to structural sinking and cracked tiles in high-end commercial projects.

This is a major hidden factor in bathtub installation cost. A heavy stone-resin tub filled with water and a guest can exceed 500kg.

How to Prevent It: Compare material weights early. If you choose a heavy model, ensure the structural engineer approves the floor load-bearing capacity. For a drop in bathtub installation, ensure the support “stringers” are specified in the pre-construction documents.

3. Misalignment of Drainage Style and On-Site Commercial Piping

Using a drainage configuration that doesn’t match the existing site piping is a leading cause of slow drainage and foul odors in hotel guest rooms.

For a business traveler, a slow drain is a 1-star review waiting to happen.

How to Prevent It: Conduct a piping simulation. Ensure the P-trap depth and the slope (minimum 1:50) are physically possible within your floor slab thickness before the hotel bathtub installation begins.

4. Vague Responsibility for Waterproofing in B2B Projects

Unclear responsibility for the waterproofing interface between the tub and the wall is the primary cause of long-term water damage in commercial hotel projects.

When the plumber thinks the tiler did the waterproofing, and the tiler thinks the plumber did it, nobody does it.

How to Prevent It: Clearly define the “Waterproofing Junction” in your contracts. Standardize the test protocol (e.g., a 24-hour flood test) before any finishings are applied.

5. Skipping the Pre-Installation Product Inspection

Failing to inspect tubs for manufacturing defects before they are tiled in significantly increases the bathtub installation cost when faulty units must be replaced.

Discovering a hairline crack after the tub is fully tiled in is a nightmare. At this point, you have to destroy the surrounding finishes to replace the unit.

How to Prevent It: Implement a strict “Arrival Inspection.” Record every unit’s condition as it comes off the truck. If it’s not perfect, it doesn’t go into the room.

6. Undefined Junctions Between Tub and Wall Finishes

Neglecting to define the exact junction between the bathtub rim and wall finishes leads to cracked sealant and mold growth in hotel environments.

How to Prevent It: Hold a “finishing coordination meeting.” Determine if the tile will sit on top of the tub flange or behind it. For a drop in bathtub installation, decide on the exact width of the grout line between the tub rim and the deck material.

7. Ignoring Long-Term Maintenance Paths for Hotel Tubs

Designing a bathtub installation without an access point for the drain or motor makes future maintenance nearly impossible without demolition.

How to Prevent It: Use a modular thinking approach. For any hotel bathtub installation, especially jetted or drop in bathtub installation models, always include an inconspicuous access panel.

8. Lack of a Standardized Installation Guide for Contractors

Failing to provide a unified installation standard for hotel contractors leads to inconsistent quality across different floors and room types.

How to Prevent It: The “Mock-Up Room” is your best friend. Install one unit perfectly, document every step, and use it as the “Gold Standard” for the entire project.

How Does Systematic Planning Reduce Project Risks?

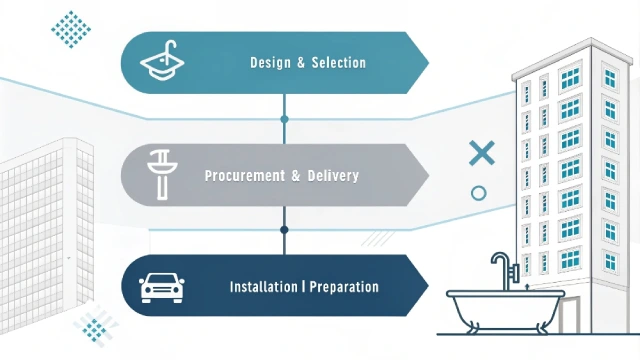

To keep your project on track, I suggest breaking your preparation into three distinct phases:

Design & Selection: Confirm all physical specs—size, weight, and drainage type.

Procurement & Delivery: Verify that the “as-delivered” product matches the “as-designed” drawings.

Installation Preparation: Lock in your waterproofing and support strategies.

By following this flow, you transform bathtub installation from a chaotic on-site scramble into a predictable assembly process. This is why choosing an “Installation-Risk-Oriented” supplier is vital. Overseas clients shouldn’t just look for the lowest price; they should look for the lowest risk.

Hotel Bathtub Installation FAQs

Q1: What is the most common cause of bathtub installation failure in hotels?

The most common cause is inadequate pre-installation planning, including unconfirmed dimensions, improper drainage alignment, and unclear waterproofing responsibilities.

Tip: Conduct a 24-hour flood test before tiling begins.

Q2: How much does poor bathtub installation increase hotel project costs?

Poor bathtub installation can significantly increase costs through rework, delayed handover, room downtime, and long-term maintenance issues, often exceeding the original installation cost.

Tip: Budget a 15% contingency for plumbing rough-in adjustments.

Q3: Is drop in bathtub installation riskier for hotels?

Drop in bathtub installation carries higher risk if access panels, waterproofing details, and structural support are not planned in advance, making pre-installation coordination essential.

Tip: Always ensure the tub weight rests on the subfloor, not the deck rim.

Q4: When should bathtub installation planning start in a hotel project?

Bathtub installation planning should begin during the design and selection phase, well before plumbing rough-in or structural work starts.

Tip: Confirm all technical drawings with the contractor before concrete pours.

Final Thoughts

I know that choosing the right partner for your bathtub installation project is a big decision. Most hotel bathtub installation mistakes are entirely preventable. When risks are identified early and addressed before installation begins, projects benefit from fewer delays, lower rework costs, and more consistent long-term performance.

If you are in the planning phase of a hotel build or renovation, our team can support your bathtub installation with technical drawings, material recommendations, and a Commercial Installation Risk Assessment checklist to reduce risk before construction begins.

We can provide a customized specification sheet to support your upcoming hotel bathtub installation and reduce project risk from day one. Feel free to contact us to get your project started on the right foot!

While proper pre-installation planning helps prevent costly on-site mistakes, long-term success also depends on selecting the right bathtub from the start. Material quality, durability, and maintenance requirements all influence installation outcomes over time.

For a complete procurement perspective, explore our guide:

How to Choose a Hotel Bathtub for Long-Term Performance: A Commercial Procurement Guide.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼