Table of Contents

Introduction — From Cost Pressure to Strategic Asset

I’ve spent over ten years collaborating with developers across North America, and one lesson stands out: the bathroom — particularly the bathtub — is no longer just a functional fixture. It is a strategic component of a property’s long-term value. In today’s market, rising construction costs and increasingly discerning tenants and hotel guests mean that every bathtub choice can impact ROI, tenant satisfaction, and marketability.

Construction costs have surged. According to the NAHB, in 2024, construction expenses represented 64.4% of a home’s sales price. Developers must now balance aesthetics, durability, sustainability, and budget simultaneously. Choosing the right bathtub is no longer a back-office decision; it is a strategic investment.

When buyers or guests enter a unit, bathrooms are one of the first spaces they notice. A well-designed, durable, and sustainable bathtub can elevate the perceived value of an entire property, while poor choices can undermine it. In residential, multiunit, and hospitality projects alike, bathtub selection has become a competitive differentiator.

Sustainability and ESG-Driven Material Value

Sustainability has shifted from being a niche trend to an essential requirement for developers. LEED and WELL certifications, along with tenant and guest preferences, make eco-friendly material selection a crucial part of property strategy.

Comparing Bathtub Materials

Cast Iron

Artificial Stone (Resin Composite)

Acrylic / Entry-Level Resin

Energy efficiency also matters. Bathtubs with superior heat retention, like cast iron and high-density artificial stone, reduce hot water consumption, increasing tenant comfort and lowering operational expenses. According to USGBC, over 547,000 housing units achieved LEED certification by 2024, highlighting the growing market expectation for sustainable building materials.

Case Insight: A hotel developer in Vancouver earned multiple LEED points simply by selecting bathtubs with 30% recycled resin content. The choice not only contributed to certification but became a marketing highlight for eco-conscious guests.

While installation efficiency directly affects ROI, another often-overlooked factor is how well your bathtub specifications match the project’s positioning. A luxury hotel and a mid-scale residential building demand very different performance and maintenance profiles.

Explore how mismatched specs can quietly undermine profitability — and how flexible bathtub design platforms solve it — in our detailed guide: Designing Bathtubs for Multi-Family and Hotel Projects: Are Your Specs Costing You?

Durability, Maintenance, and Lifecycle Cost

Durability is a key driver of ROI. The choice of bathtub affects maintenance frequency, replacement needs, and long-term asset value. With construction material inflation averaging over 10% annually for items like cement, glass, and paint (NAIOP 2023), choosing durable materials is more critical than ever.

Material Lifecycle Comparison

Below is a comparison of common bathtub materials, highlighting their cost, durability, maintenance needs, and overall lifecycle impact. Understanding these factors helps developers and designers make sustainable, long-term investment decisions.

Cast Iron

Artificial Stone

Acrylic

Entry-Level Resin

Real-world example: In a 200-unit apartment project, inexpensive acrylic tubs cracked within three years, triggering complaints and high maintenance costs. Replacing 40 tubs ultimately cost more than investing in higher-quality materials upfront. In contrast, a hotel developer who invested $150 extra per unit on resin composite tubs saved $400 per unit over ten years.

For a deeper dive into this topic, see our article How Sustainable Bathtub Materials Boost Profitability and ESG Success for Developers. It breaks down how recycled composites, low-VOC coatings, and modular packaging not only meet LEED standards but also deliver measurable profitability gains over time.

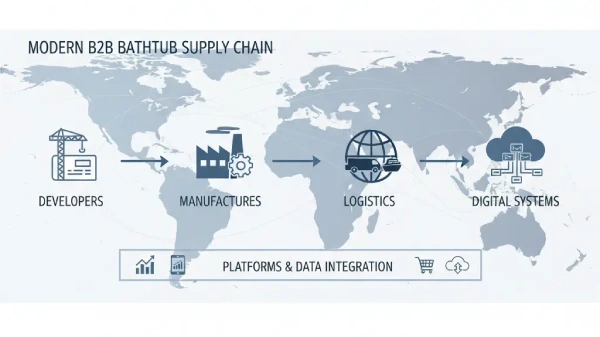

Supply Chain Reliability and Digital Efficiency

Supply chain instability can significantly affect project timelines and budgets. Delays in bathtub delivery cascade into lost revenue, increased financing costs, and construction overruns.

How Digital Supply Chain Management (DSCM) Mitigates Risks

- Real-Time Visibility: End-to-end tracking from raw materials to on-site delivery.

- Predictive Lead-Time Forecasting: Enables Just-In-Time (JIT) delivery, reducing storage costs.

- Proactive Risk Mitigation: Anticipates potential shortages and identifies alternative sources.

Construction Dive (2024) reports that global material price volatility directly impacts developer timelines. Developers who rely on partners with DSCM and reliable logistics gain predictable schedules and reduced financial risk.

Beyond developers’ ROI, digital supply chains are transforming profitability across the entire sanitary ware ecosystem. For wholesalers, streamlined SKU management and standardized materials now directly drive margin gains. Learn How Digital Supply Chains Guarantee ROI for North American Sanitary Ware Wholesalers.

Design Customization and Installation Efficiency

Digital tools and modular design improve both customization and installation:

Traditional vs Digital/Modular Approach

Comparing traditional workflows with modern digital and modular approaches reveals how project efficiency, customization, and installation quality can be dramatically improved.

Customization

Multiple CAD revisions; long mold times

Real-time configurator; direct CNC production

Installation

Multi-trade on-site coordination; high QC risk

Pre-assembled units; drop-in installation

A Florida hospitality project reduced bathroom installation time by 30% using modular tubs, opening three weeks earlier and capturing peak-season revenue. Digital configurators also allowed developers to tailor tub dimensions, colors, and features for specific layouts, enhancing perceived value.

However, efficient installation alone doesn’t guarantee higher ROI. Procurement missteps — from inconsistent supplier coordination to short-term cost chasing — can silently erode profit margins. Our related article, Why Does Your Bathtub Procurement Strategy Undermine Project ROI?, explores how strategic sourcing alignment helps developers avoid costly delays and warranty disputes, turning procurement into a true ROI driver.

Conclusion — Building Smarter, Faster, and Greener

Bathtub selection is no longer a minor procurement decision; it is a strategic asset choice impacting sustainability, durability, efficiency, and ROI. Developers who prioritize lifecycle value achieve:

Key Project Outcomes

- ✅ Reduced long-term maintenance and replacement costs

- ✅ Enhanced sustainability credentials (LEED / WELL points)

- ✅ Higher tenant and guest satisfaction

- ✅ Predictable construction timelines and reliable delivery

To achieve measurable ROI gains while meeting sustainability and schedule goals, developers should consider the following priority actions:

Strategic Procurement Recommendations

- Evaluate total lifecycle cost, not just upfront price.

- Prioritize suppliers offering EPDs, digital customization, and modular solutions.

- Consider durable, repairable materials that reduce mid-cycle replacement risk.

- Integrate digital supply chain management to mitigate delays and cost volatility.

By treating bathroom design and bathtub selection as strategic assets, developers can differentiate their properties, reduce costs, and maximize ROI. In today’s competitive North American market, building smarter, faster, and greener starts with a single — yet critical — choice: the bathtub.

Choose George Build Shop as your trusted partner in building smarter, faster, and greener — from material selection to full-scale bathtub procurement.

We provide integrated one-stop bathroom solutions covering tubs, sanitaryware, fittings, and system coordination for hotel and commercial projects.

▼ Submit the form below to connect with our team and explore project-based collaboration. ▼