Why Most Hotel Whirlpool Bathtub Problems Are Decided Long Before Installation?

Hello, I’m Helen. Over the past ten years in the sanitary ware industry, I’ve walked through hundreds of construction sites, sat in countless MEP (Mechanical, Electrical, and Plumbing) coordination meetings, and helped hotel developers across five continents source the right fixtures. Over the years, commercial whirlpool bathtubs for hotel projects have consistently been one of the highest-risk bathroom specifications I encounter.

If you are a hotel owner, developer, or project manager, you know that a commercial whirlpool bathtub is a double-edged sword. On one hand, it’s the ultimate symbol of luxury—the “hero” feature of a premium suite that justifies a higher ADR. On the other hand, it is often the single biggest headache for the maintenance department.

In this article, I’ll walk you through how commercial whirlpool bathtubs actually perform in hotel environments, what drives the real cost of whirlpool bathtub ownership, and how early specification decisions can either protect—or quietly destroy—your project budget—from a hotel project perspective, not a residential one.

My core insight from a decade in the field is this: Most problems with hotel whirlpool bathtubs are not caused by poor products or cleaning, but by early specification and design decisions made during the planning phase that ignored commercial realities.

Table of Contents

What Makes a Whirlpool Bathtub “Commercial-Grade” for Hotels?

In the residential world, a bathtub is used perhaps once a week. In a high-occupancy resort, it faces daily use by guests who aren’t familiar with the controls.

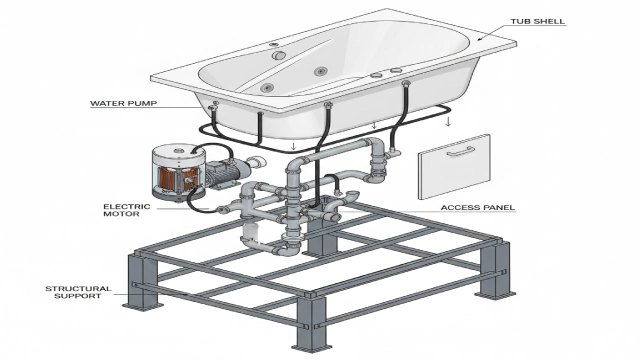

A commercial bathtub for hotel use is not defined by size or luxury, but by how well it integrates into the building’s structural, plumbing, and maintenance systems. In other words, a commercial whirlpool bathtub behaves more like a building system than a standalone product.

These are not optional features—they are baseline requirements for any commercial bathtub expected to survive hotel operations:

The Structural Load: A filled 1800mm commercial bathtub plus a guest can weigh over 500kg. Was the floor slab reinforced during the design phase, or will you risk structural remediation later?

The Pump Duty Cycle: Residential pumps aren’t designed for the back-to-back usage of a busy hotel.

The Drainage System: High-flow jets require rapid drainage to meet turnover times.

Maintenance Access: Is there a concealed, aesthetic panel to reach the motor? Failing to plan for this means breaking expensive finishes when a simple sensor needs replacing.

Source: Hot Tub Market – Growth, Future Prospects and Competitive Analysis, 2024 – 2032

How Whirlpool Bathtubs Are Actually Used in Hotel Environments?

In a showroom, a whirlpool bathtub looks serene. In a hotel, it faces a “brutal” environment. This distinction between residential assumptions and hotel bathtub reality is often underestimated during specification.

Non-Professional Users: Guests press buttons repeatedly, use unapproved bubble baths that clog the intake, or run the jets without enough water—dry-burning the pump.

Chemical Exposure: Hotel bathtub cleaning agents are much harsher than home cleaners. Lower-grade jet finishes will corrode within months.

The “Hidden” Biofilm: If the pipework isn’t designed for full gravity drainage, stagnant water sits in the lines, creating odors.

None of these are edge cases—they are daily realities in hotel operations that must be addressed during the design phase.

Many hotel jetted tub failures are already “designed in” long before opening day—this article explains why most problems occur during specification and coordination, not during guest use.

👉 Read more: Why Do Most Hotels with Jetted Tubs Fail Before the First Guest Checks In?

Source: Pros and Cons of Whirlpool Tubs

What Are the Most Common Failure Points in Hotel Whirlpool Bathtub Projects?

Why do so many whirlpool bathtub manufacturers receive complaints just six months after hotel installation? It’s rarely a random manufacturing defect.

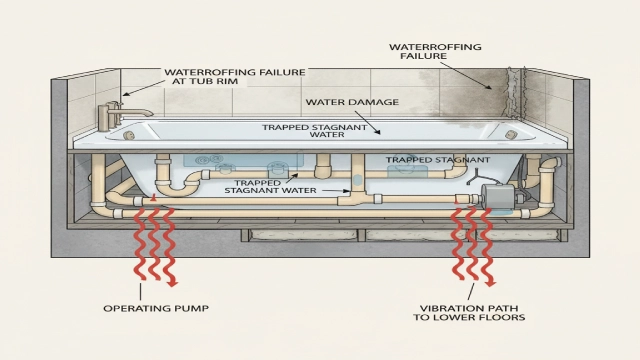

Most commercial whirlpool bathtub failures in hotels come down to three predictable issues: poor drainage design, vibration and noise control, and inadequate waterproofing.

Residual Water & Odor: If the internal piping isn’t “V-sloped,” water stays trapped, resulting in a “musty” room smell—a top reason for negative TripAdvisor reviews.

Noise Complaints: I’ve seen projects where powerful motors were installed without vibration-dampening mounts, leading to noise complaints from the rooms below.

Leakage and Waterproofing: This is the most expensive failure. If the hotel bathtub rim design doesn’t allow for a perfect seal, water will seep into the subfloor.

These failures follow predictable patterns set during early design and specification—not necessarily product quality. In most hotel projects, these outcomes are already determined before the bathtub is even delivered to site.

Why Design and Specification Decisions Matter More Than Product Choice?

This is the logic center of my work: Once a commercial whirlpool bathtub is installed in a hotel, most specification mistakes become either irreversible or prohibitively expensive to correct. At that point, the cost of correcting mistakes often exceeds the original cost of the whirlpool bathtub itself.

Early coordination on commercial whirlpool bathtub projects must include:

MEP Coordination: Ensuring the electrical load is accounted for in the circuit breakers.

Waterproofing Integrity: Designing the “lip” of the tub to act as a water barrier.

The Real Cost of Whirlpool Bathtub Integration: Factoring in the structural and plumbing requirements before the slab is poured.

Early specification decisions determine long-term performance far more than brand or feature selection.

If you’re defining whirlpool bathtubs at the design stage, this guide outlines the key commercial specifications that separate residential products from hospitality-grade systems.

👉 Read more: What Are the Key Specifications for Commercial Whirlpool Bathtubs in Hospitality Projects?

How Do Maintenance, Hygiene, and Daily Operations Affect Whirlpool Bathtubs in Hotels?

I often hear hotel managers complain that whirlpool tubs are “unhygienic.” But in hospitality projects, hygiene failures are a brand and review-score risk.

In the commercial whirlpool bathtub world, we prioritize Ozone Disinfection and Pipe Flushing systems. In high-occupancy hotels, hygiene systems must be automated by design—not enforced by staff discipline. If these aren’t specified in the original order, your staff will struggle to maintain safety standards under tight turnover times.

What appears to be a simple question about cleaning jetted whirlpool tubs often exposes much deeper design and specification risks—this article explains why maintenance challenges in hotels are usually decided long before daily operations begin.

👉 How to Clean a Jetted Whirlpool Tub: Is This Maintenance Question Hiding a Massive Project Risk?

What Is the Real Cost of Whirlpool Bathtubs Beyond the Initial Purchase Price?

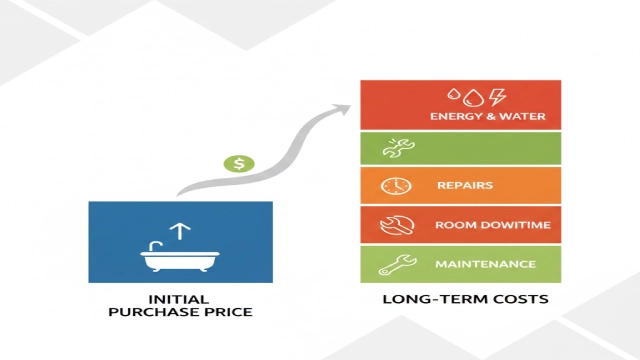

When developers evaluate the cost of a whirlpool bathtub for a hotel project, they often underestimate the five-year lifecycle cost. The real cost of a whirlpool bathtub in a hotel project is the combined cost of procurement, installation, and maintenance.

Maintenance Labor: How many man-hours are spent descaling jets?

Room Downtime: If a tub is out of order, you cannot sell the room at full price.

Spare Parts: Can you get a replacement PCB in 48 hours, or do you have to wait six weeks for an international shipment?

When analyzing the cost of whirlpool bathtub ownership, a cheaper unit that causes room downtime is significantly more expensive than a premium unit that runs flawlessly for years.

To understand what hotel whirlpool bathtubs truly cost, this breakdown explains how product grade, installation, compliance, and long-term maintenance shape the real project budget.

👉 Read more: How Much Does a Whirlpool Bathtub Really Cost in Hotel Projects?

Source: Bathtub Market

When Whirlpool Bathtubs Make Sense — And When They Don’t?

This is ultimately an operational decision, not just a design preference. The right question is: “Can our operation support them without hidden costs?”

They Make Sense for: Luxury resorts, boutique villas, and premium suites where the guest expects a “spa” experience and stays longer.

They Don’t Make Sense for: High-turnover business hotels or quick renovation projects where the existing plumbing cannot handle the flow requirements.

Building trust means telling a client when a product doesn’t fit their operational reality.

Even when whirlpool bathtubs make sense for your hotel or resort, choosing the right supplier is essential to ensure system reliability, compliance, and long-term operational efficiency — read our full guide on selecting the best whirlpool bathtub supplier for hotel and resort projects.

👉 Read more: How to Choose the Right Whirlpool Bathtub Supplier for Hotel & Resort Projects?

What Role Do Project-Focused Suppliers Play in Reducing Risk in Hotel Whirlpool Bathtub Projects?

Why is a “catalog supplier” dangerous? Because they sell you a box. They don’t ask about your floor slab or drainage slope.

This is where project-focused suppliers differ fundamentally from traditional whirlpool bathtub manufacturers. At George Group, we provide specification support at the concept, design, and coordination phases. Addressing early risks requires a partner who understands hospitality operations—not just factory production. We are here to de-risk your project.

Conclusion: Designing Success Before the Water Runs

Most problems with hotel whirlpool bathtubs are decided long before guests ever turn them on. By the time a guest experiences a leak, the fate of that hotel bathtub was likely sealed eighteen months prior.

If your hotel or resort project is currently in the design, tender, or procurement phase, we offer a complimentary technical review of your bathroom layout to identify potential MEP, drainage, or maintenance risks before specifications are finalized.

Would you like me to review your current bathroom floor plans to identify potential risks? Reach out to Helen and the team at George Group today—let’s ensure your project’s luxury features are built to last.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼