Direct Answer: What Bathtub Material Has the Lowest 10-Year TCO for Hotels?

For hotels with occupancy above 75%, solid surface bathtubs deliver the lowest 10-year Total Cost of Ownership (TCO)—typically 30–40% lower than acrylic bathtubs. Their superior repairability, resistance to commercial cleaning chemicals, and long service life eliminate frequent replacement cycles and reduce room downtime.

Bottom Line: Solid surface bathtubs provide the best long-term ROI for high-occupancy hotels, while acrylic bathtubs should only be considered for low-use economy rooms.

This is a true lesson learned: One major hotel chain replaced 120 acrylic bathtubs within 18 months—a costly mistake totaling $180,000 in materials, labor, and lost bookings. The issue was not installation quality, but choosing the wrong bathtub material for a high-traffic property. This case illustrates how material selection—not workmanship—is often the primary driver of premature bathtub failure in hotels.

In hotel operations, the selection of hotel bathtub materials is the single most critical factor determining your 10-year Total Cost of Ownership (TCO). The wrong choice leads to frequent replacements, extended room downtime, and negative guest reviews—driving costs up by as much as 60% over a decade.

I’m Helen, with over 10 years of experience advising hotel developers, operators, and procurement teams on commercial sanitary ware selection across Asia, Australia, and the Middle East. My work focuses on helping hotels avoid costly lifecycle mistakes caused by selecting bathtub materials based solely on initial price rather than long-term performance and TCO.

What Will You Learn in This Guide?

This guide answers the most common procurement questions hotel owners ask when evaluating bathtub materials for long-term ROI.

Pros and cons of four essential commercial bathtub materials

A 10-year bathtub comparison with full TCO analysis

How to choose the right bathtub material based on hotel category and occupancy rate

Table of Contents

Which Bathtub Material Is Best for Each Hotel Category?

Your hotel’s category and average occupancy rate fundamentally determine the optimal bathtub material. Durability is non-negotiable for high-traffic properties.

Bathtub Material Comparison (Commercial Use)

Acrylic Bathtub

- Cost: $

- Lifespan: 3–7 years

- Best For: Economy hotels (<70% occupancy)

- Key Benefit: Lowest upfront cost

Solid Surface Bathtub

- Cost: $$

- Lifespan: 12–20 years

- Best For: Upscale hotels (>75% occupancy)

- Key Benefit: Best long-term ROI

Cast Iron Bathtub

- Cost: $$$

- Lifespan: 25–50+ years

- Best For: Boutique / heritage hotels

- Key Benefit: Premium aesthetic + durability

Enameled Steel Bathtub

- Cost: $$

- Lifespan: 10–15 years

- Best For: Mid-scale hotels (with sound control)

- Key Benefit: Cost–durability balance

For modern hotels with high room turnover, solid surface bathtubs are the most versatile commercial bathtub material, delivering the lowest lifecycle cost while meeting durability and guest experience expectations. Acrylic bathtubs are suitable only where usage intensity is low.

Source:

What Are the 4 Main Commercial Bathtub Materials Used in Hotels?

Selecting commercial bathtub materials is a strategic procurement decision with long-term operational impact. Below is a professional comparison of the four most common options.

Acrylic Bathtub

Are Acrylic Bathtubs Suitable for High-Occupancy Hotels?

No. Acrylic bathtubs carry the highest replacement risk in high-occupancy hotels due to surface scratching, chemical sensitivity, and structural flexing under daily use.

Why Do Acrylic Bathtubs Fail Early in Hotels?

Acrylic bathtubs fail early in hotels due to frequent chemical cleaning, surface scratching, and structural flexing under high daily usage, often requiring replacement within 3–5 years.

Pros: Lowest initial cost ($250–500); lightweight (60–100 lbs) for easy installation; warm surface; minor scratches can be buffed.

Cons: Short commercial lifespan; scratches easily; sensitive to harsh cleaners; prone to yellowing over time.

Cost Reality: Replacing a $300 acrylic bathtub every five years results in $600 in material costs alone over 10 years, excluding labor and lost bookings.

Best for: Economy hotels or properties with bathtub usage below 60% occupancy.

Solid Surface Bathtub

Why Are Solid Surface Bathtubs the TCO Winner for Hotels?

Solid surface bathtubs deliver the lowest 10-year TCO in high-traffic hotels because they are fully repairable, chemically resistant, and designed for long commercial lifecycles.

Is Solid Surface the Best Bathtub Material for High-Occupancy Hotels?

Yes. Solid surface bathtubs are widely considered the best option for hotels with occupancy above 75% due to their repairability, chemical resistance, and long commercial lifespan.

Pros: 12–20 year lifespan; fully repairable on-site; non-porous and hygienic; excellent resistance to commercial cleaners; good heat retention.

Cons: Higher upfront cost ($550–1,200); heavier than acrylic; limited color palette; longer lead times.

ROI Insight: Despite costing up to 80% more initially, solid surface bathtubs typically reduce 10-year TCO by 30–40%. In a 200-room hotel, this can translate to over $80,000 in savings.

Best for: Upscale hotels, resorts, and any high-occupancy property prioritizing long-term ROI.

Cast Iron Bathtub

When Does a Cast Iron Bathtub Make Sense for Hotels?

Cast iron bathtubs are best reserved for luxury suites and heritage hotels where structural capacity has been verified and long-term aesthetic value outweighs installation complexity.

Are Cast Iron Bathtubs Suitable for All Hotel Projects?

Cast iron bathtubs are best suited for boutique or heritage hotels with verified structural capacity and are not recommended for retrofits without engineering assessment.

Pros: Extremely durable (25–50+ years); premium feel; excellent heat retention; timeless aesthetics.

Cons: Very heavy (300–500 lbs); high purchase cost; complex installation; expensive enamel repairs.

Critical Warning: Always verify floor load capacity. One Chicago hotel spent $40,000 on structural reinforcement after skipping this step.

Enameled Steel Bathtub

Why Is Enameled Steel a Risky Choice for Guest Satisfaction?

Enameled steel bathtubs frequently generate guest complaints due to noise resonance, cold surfaces, and poor heat retention, making them a high-risk option in mid-scale hotels.

Why Do Hotels Avoid Enameled Steel Bathtubs?

Hotels often avoid enameled steel bathtubs due to noise complaints, poor heat retention, and denting risks that negatively impact guest satisfaction.

Pros: Moderate cost; lighter than cast iron; non-porous enamel surface.

Cons: Loud water noise; cold surface; poor heat retention; dent-prone steel.

Verdict: Rarely recommended unless factory-applied sound dampening is included.

Source:

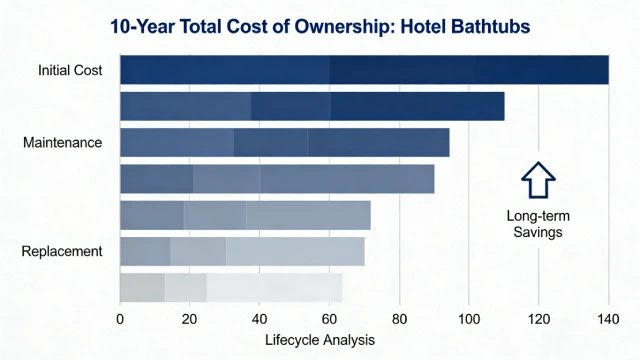

How Much Does Each Bathtub Material Really Cost Over 10 Years?

The 10-year Total Cost of Ownership (TCO) reveals the real financial impact of bathtub material selection beyond upfront price.

10-Year TCO Formula:

10-Year TCO = Initial Cost + (Annual Maintenance × 10) + Replacement Cost

Example: 150-Room High-Occupancy Hotel:

Bathtub 10-Year TCO Comparison

Acrylic

- Initial Cost: $52,500

- Maintenance / Year: $7,500

- Replacements: $105,000

- 10-Year TCO: $232,500

Solid Surface

- Initial Cost: $105,000

- Maintenance / Year: $4,500

- Replacements: $0

- 10-Year TCO: $150,000

Cast Iron

- Initial Cost: $150,000

- Maintenance / Year: $3,000

- Replacements: $0

- 10-Year TCO: $180,000

This TCO comparison confirms that solid surface bathtubs are the most cost-efficient choice for high-occupancy hotels, saving approximately $80,000 per 150 rooms over 10 years compared to acrylic by eliminating replacement cycles.

How Should Hotels Choose the Right Bathtub Material?

Step 1: Assess Occupancy-Adjusted Usage

<60% occupancy: Acrylic may be viable

75% occupancy: Invest in solid surface or cast iron

Step 2: Verify Structural Capacity

Upper floors / older buildings: Avoid cast iron without engineering review

New builds: All options possible

Step 3: Match Guest Expectations

Economy guests value cleanliness and function

Luxury guests perceive material quality as part of brand value

What Are the Top 3 Bathtub Procurement Mistakes Hotels Should Avoid?

Most costly bathtub failures stem from procurement decisions made before construction begins.

Choosing based on initial cost only

Skipping structural assessment

Using residential-grade materials in commercial hotels

FAQ: Common Hotel Bathtub Procurement Questions

Q: Is solid surface really worth twice the cost of acrylic?

A: Yes. For hotels with occupancy above 70%, solid surface bathtubs typically deliver 30–40% lower 10-year TCO due to superior repairability and lifespan.

Q: Can hotels mix bathtub materials within one property?

A: Yes. Many hotels use acrylic or solid surface in standard rooms and premium materials in suites to balance cost and guest expectations.

Key Takeaway for Hotel Procurement Teams

For high-traffic hotels, bathtub material selection is not a design decision but a long-term operational investment that directly determines 10-year ROI.

Ultimately, bathtub material selection drives your long-term operating cost, but knowing where it fits into the broader procurement journey helps your hotel team make better decisions.

For a step-by-step procurement roadmap — from material selection, size analysis, installation standards through to inspection and lifecycle optimization — see our Hotel Bathtub Procurement Guide. This guide consolidates all the essential decisions into one actionable framework for commercial projects

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼