Hello to the project managers, asset owners, and developers who keep the hospitality industry moving. I’m Helen. Over the past decade, I’ve advised on dozens of hotel developments—from boutique luxury resorts to 500-room metropolitan properties.

Throughout my career, I have shifted from being a product specialist to a systemic observer. I’ve watched the same patterns of operational failure repeat themselves across different regions, brands, and budgets. There is a specific, recurring financial friction that surfaces during the second or third year of operation. It usually begins with a phone call from a facility manager who is watching their bathtub maintenance budget deviate significantly from their initial projections.

They often ask the same question:

“Helen, we clean the rooms every single day—why do our tubs look ten years old long before the asset is supposed to enter its first major renovation cycle?”

I’ve heard this exact question in hotels from Dubai to Southeast Asia. The uncomfortable truth is this: Hotel bathtub maintenance costs keep rising not because hotels clean too little or too much, but because bathtubs are specified without accounting for how they will be used, stressed, and cleaned—every single day.

If you’re seeing your maintenance ledger climb, it isn’t necessarily an operational failure. It is a locked-in cost structure. This is a specification problem, not a housekeeping one.

To fully understand why maintenance costs keep rising, it’s important to look at the root causes of hotel bathtub cleaning problems. Our in-depth analysis in Why Hotel Bathtub Cleaning Problems Keep Happening and How to Fix Them highlights common pain points—from material selection and design flaws to cleaning chemical effects—that directly contribute to recurring maintenance issues. By addressing these factors early in the specification and design phases, hotel developers and facility managers can significantly reduce long-term costs and avoid repeated problems.

Table of Contents

Why Are Rising Maintenance Costs a Design Outcome Rather Than an Operational Failure?

The long-term trend of your bathtub maintenance cost is decided the moment the procurement contract is signed. Current procurement frameworks often inadvertently reward upfront savings over long-term performance. While a developer may select a bathtub based on a beautiful catalog photo and a low initial price point, they are effectively pre-ordering a decade of high operational expenses.

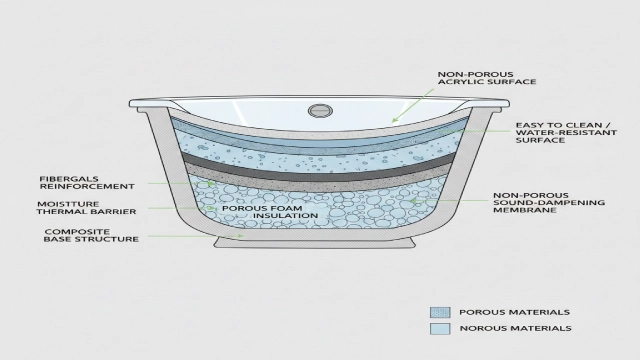

From a lifecycle cost perspective, material and surface technology dictate three critical liabilities:

-

Recurring Labor & Chemical Load: If the material is porous, it demands more labor-hours and aggressive chemicals to reach “guest-ready” standards, inflating the daily OPEX.

-

Accelerated Depreciation Risk: When a surface degrades prematurely, the asset loses value faster than the accounting model predicted, leading to an early bathtub replacement cost shock.

-

Capex Shock Events: If a material is not repairable, a single guest accident (like a dropped heavy object) necessitates a full unit replacement rather than a minor fix.

From a boardroom perspective, your operations team doesn’t “create” these costs; they simply manage the consequences of the initial specification.

How Does High-Frequency Use Turn Minor Surface Wear into a Permanent Maintenance Issue?

A hotel bathtub is not a residential fixture; it is a high-utilization industrial asset. This distinction is often underestimated during the specification phase. In a high-occupancy hotel, a tub might see 300+ guests a year, each introducing different minerals, jewelry, and chemical products into the environment.

When people ask me how to maintain bathtub surfaces in a commercial setting, my answer is always the same: You cannot maintain what the material itself cannot support.

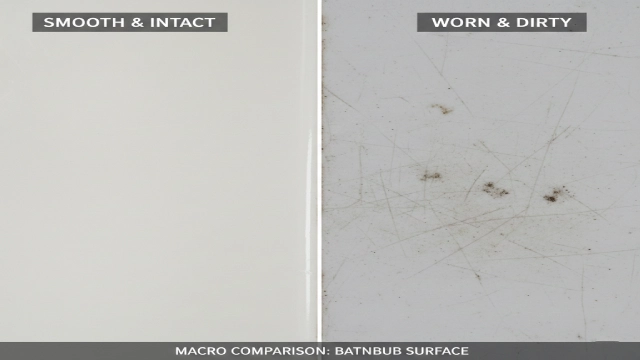

In one project I audited, the bathtub maintenance hours per room doubled in the second year—without any change in staffing levels or cleaning standards. The surface had become micro-scratched from high-frequency use. These microscopic valleys in the material “grabbed” dirt and soap scum, requiring housekeepers to scrub twice as hard to achieve the same result.

In the hospitality world, Time = Labor Cost. When cleaning time increases by even five minutes per room due to surface degradation, it translates into a massive, unbudgeted OPEX increase across a 300-room property.

Why Don’t Cleaning Chemicals Create the Problem, but Instead Expose It?

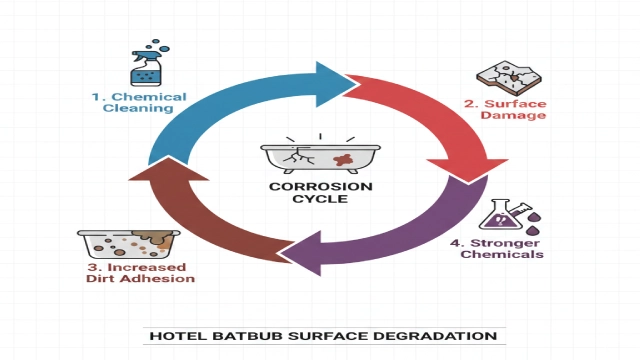

Commercial cleaning is a non-negotiable requirement for brand standards. Teams must use alkaline or acidic cleaners to strip minerals and bacteria quickly. If the bathtub material is low-grade, these chemicals act as a slow-motion solvent.

There is a common industry myth that “gentle cleaning” will extend the life of a low-cost tub. However, hotel operations cannot afford to be gentle. If a material requires special handling, it is fundamentally unfit for a hotel environment.

Once this “Corrosion Loop” starts, it is operationally very difficult to stop:

Stronger chemicals are needed to clean a worn, porous surface.

These chemicals damage the surface further.

The surface attracts more dirt, requiring even harsher chemicals.

Based on recent hotel renovation projects I’ve overseen, this cycle often forces a total unit failure within the first 4 years. Today’s market rates for bathtub replacement cost—including labor, disposal, and the high cost of skilled plumbing—can easily range from $2,000 to $8,000 per room.

How Does Structural Damage Multiply Costs Beyond the Bathtub Itself?

From a risk management perspective, not all failures are equal. While surface wear is an aesthetic issue, structural failure is a property-wide risk that impacts building integrity.

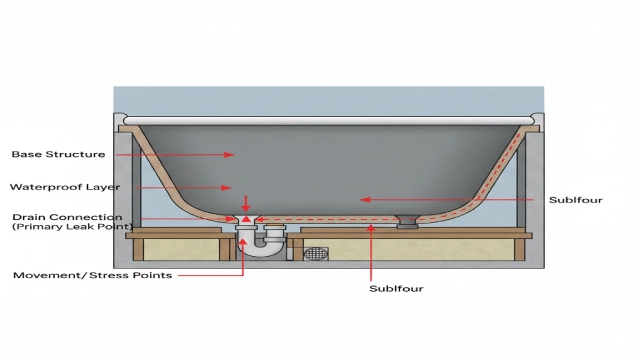

The Strategic Importance of Bathtub Drain & Base Design

One of the most overlooked aspects of bathtub drain maintenance is the structural rigidity of the tub. In many value-engineered tubs, the base is not sufficiently reinforced. When a guest stands in the tub, the floor deflects. This movement puts immense pressure on the drain seal and the surrounding waterproof envelope.

Every millimeter of movement is a future repair bill. If the tub flexes, the seal eventually breaks, leading to:

Subfloor Leaks: Water damage that travels into the ceiling of the room below.

Structural Mold: High-cost remediation that can shut down entire room blocks.

These failure paths turn a simple plumbing fix into a massive structural repair bill. At George Group, we help teams model these outcomes early, ensuring the structural rigidity is designed for the weight and pressure of commercial use.

What Is the Hidden Cost That Most Hotel Whirlpool Bathtub Budgets Ignore—Room Downtime?

For any CFO or Asset Manager, the most painful cost isn’t the repair itself; it’s the “Dark Room.” If a room is out of service for three days because of a bathtub maintenance issue or a complex repair, you aren’t just paying for the plumber. You are losing the most perishable commodity in your business: room nights.

We use a conservative estimate to model this loss:

Loss = Days of Downtime × ADR (Average Daily Rate) × Occupancy %

If your ADR is $250 and your occupancy is 80%, a 3-day downtime for a single room costs you $600 in lost revenue. If 20 rooms are affected by a recurring specification error, the revenue loss exceeds the entire initial cost of the bathtubs. Downtime turns a maintenance issue into a revenue problem.

Source: BusinessPlan Templates – Hotel Operating Cost Structure

Why These Costs Keep Repeating Across New Projects?

These are systemic issues, not individual mistakes. Why does the industry continue to specify products that lead to rising maintenance costs?

-

Siloed Decision Making: Procurement frameworks often reward “Day 1” savings without consulting operations on “Year 3” costs.

-

Lack of Life-Cycle Costing: Budgets fail to account for the labor-hour increase as surfaces degrade.

-

Legacy Assumptions: Specifying residential-grade materials for high-occupancy commercial environments.

At George Group, our role is to help teams model outcomes rather than just select products. We provide the data that allows you to test your assumptions before they become permanent line items in your maintenance ledger.

Conclusion — Cost Control Starts Before Installation

The lesson of my ten years in the industry is that a bathtub that looks affordable at installation can become one of the most expensive fixtures over its lifetime. True cost control is a proactive strategy. To protect your margins:

Audit the Material: Ensure it is chemically resistant to commercial cleaning standards.

Verify Structural Rigidity: Eliminate deflection to protect the integrity of the bathtub drain maintenance seal.

Think in Lifecycles: Weigh initial savings against the potential for bathtub replacement cost and revenue-killing room downtime.

Lowering your long-term maintenance burden starts with a conversation about durability. If you are currently planning a hotel project, let’s look at the performance data together.

Would you like to see our comparative analysis on how different bathtub materials perform after three years of commercial use? I’m happy to share the internal data we use to help our partners model long-term OPEX. Contact George Group today, and let’s discuss how to secure your investment.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼