I’ve worked with distributors and project developers around the world for more than a decade. I understand what keeps procurement managers like Michael awake at night: finding the right balance between cost, delivery, and reliability. Too often, people chase the lowest unit price and ignore what that cheap number hides—quality issues, delays, and warranty losses.

In my experience, the foundation of a truly profitable vanity business isn’t price. It’s durability—and how well your materials adapt to the environment where they’re installed. That’s what separates a short-term deal from a long-term partnership.

Table of Contents

Why Does Material Choice Determine the Market Success of Bathroom Vanities?

The vanity market is crowded, and everyone is fighting for the same shelf space. Many wholesalers focus on design and front-end pricing, but they underestimate how much material durability determines profitability.

Durability isn’t just about looks or engineering—it’s a business strategy. The materials you choose define how long your products last, how customers perceive your brand, and how often you deal with replacements. I’ve seen entire product lines fail simply because the wrong material was used in the wrong environment.

Here’s my key insight: durability is the foundation of competitiveness, and the right material depends on environmental conditions. Before choosing a substrate, always consider humidity, temperature shifts, and cleaning frequency. The smartest approach is to bridge design and practicality—help your clients choose materials that match their environments. That’s how you protect your margin and reputation.

How Does Durability Directly Affect Profit and Long-Term Value?

For B2B buyers, durability is not a luxury feature—it’s a financial decision. A slightly higher upfront cost often prevents major expenses later.

A few years ago, I worked with a developer building a large condominium complex near the ocean. They had specified low-cost particleboard vanities. I warned them that coastal air—rich in salt and moisture—would destroy those units within a few years.

Our projections showed a 30% failure rate within three years, which would have cost thousands in warranty claims and labor. We switched to marine-grade plywood with moisture-sealed edges. That added just 12% to the unit cost, but it completely eliminated the failure risk. Three years later, the project reported zero material-related issues.

That’s what I call “profitable durability.” You spend a little more, and you save a lot more.

In hotels, durable vanities mean fewer room closures and more revenue. In public spaces, they mean lower maintenance and fewer replacements. Durability—matched to the environment—is the single best way to protect ROI.

How Should Environmental Conditions Guide Material Selection?

After seeing so many projects struggle with material failures, I now start every client consultation with a simple question:

“Where will these vanities live?”

Climate and humidity are the two biggest threats to performance. The same vanity that thrives in Alberta may fail fast in Miami. Choosing materials based on the environment is how you avoid warranty pain later.

When I help B2B clients specify vanities, I don’t just ask about the design—I ask about the location.

🌊 Coastal or Humid Regions

Avoid MDF and particleboard — they easily absorb moisture.

✅ Choose PVC board or WBP plywood with sealed edges instead.

- PVC: fully waterproof.

- Marine-grade plywood: bonded with WBP glue, resists humidity and salt air.

💡 For structure, use aluminum framing — strong and corrosion-resistant.

❄️ Dry or Cold Regions

You can safely use solid wood or veneered plywood.

These materials offer a warm, high-end appearance without the risk of swelling.

🏢 High-Traffic Commercial Projects

Prioritize durability above all.

- HDF with HPL finishes withstands impact and frequent cleaning.

- Stainless steel frames ensure long-term stability and easy maintenance.

Selecting materials this way isn’t guesswork—it’s technical specification. Match the product lifespan to the stress of the environment, and you’ll dramatically reduce warranty claims and customer complaints.

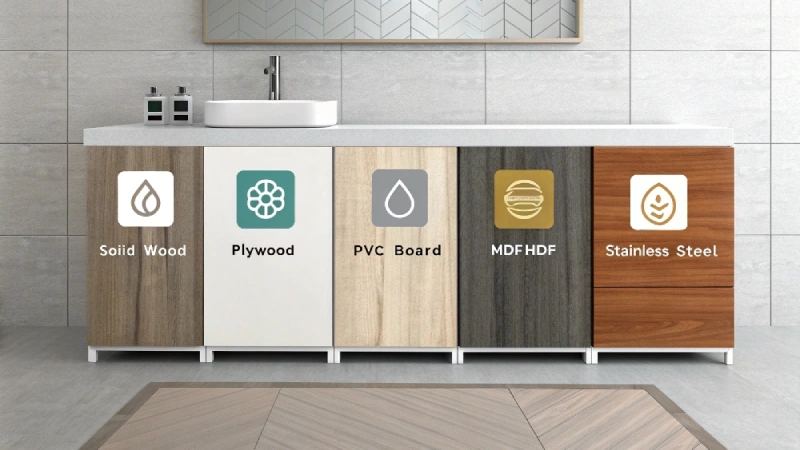

What Are the Key Differences Among Major Vanity Materials?

To make material selection easier, here’s how I usually help procurement managers evaluate their options:

🧱 Material Comparison for Bathroom Vanities

🌳 Solid Wood

Durability: ★★★★☆

Best Environments: Dry, stable climates

Relative Cost Tier: $$$$

B2B Advantages: Premium look, strong brand perception

🪵 Plywood

Durability: ★★★★☆

Best Environments: Moderate humidity

Relative Cost Tier: $$$

B2B Advantages: Balanced cost and reliability

💧 PVC Board

Durability: ★★★★★

Best Environments: Humid, coastal zones

Relative Cost Tier: $$$

B2B Advantages: Fully waterproof, low maintenance

🪑 MDF / HDF

Durability: ★★★☆☆

Best Environments: Indoor, low-humidity

Relative Cost Tier: $$

B2B Advantages: Affordable, easy to customize

⚙️ Aluminum / Stainless Steel

Durability: ★★★★★

Best Environments: High-traffic, commercial

Relative Cost Tier: $$$$

B2B Advantages: Corrosion-resistant, recyclable

I often remind clients: don’t look at cost alone—look at cost versus performance. MDF may seem economical, but in a high-humidity apartment, it can fail in three years. PVC, on the other hand, might last eight years or more.

Plywood sits comfortably in the middle—strong, adaptable, and perfect for stable residential environments. Just make sure it meets CARB or EPA emission standards for safety and compliance.

The right material is the one that performs as promised, in the environment where it will live. That’s what keeps your clients happy and your profit stable.

How Can We Match the Right Materials to Different Project Types?

Every project type has its own functional priorities. A residential vanity faces different stress than a hotel or public restroom. Here’s how I approach it:

🏗️ Project Type & Material Recommendations

🏠 Residential Projects

Functional Priority: Design appeal and long-term use

Recommended Substrates: Plywood, sealed MDF, solid wood

Relative Maintenance Cost: Medium

🏨 Hospitality Projects

Functional Priority: High frequency cleaning, humidity resistance

Recommended Substrates: PVC board, HDF, premium plywood

Relative Maintenance Cost: Low

🏢 Commercial / Public Projects

Functional Priority: Impact and corrosion resistance

Recommended Substrates: Stainless steel, aluminum, HPL finishes

Relative Maintenance Cost: Very Low

One of my clients—a hotel chain with properties in a coastal area—used MDF vanities for their first two resorts. Within 18 months, the units near showers started to swell and crack. Maintenance costs went 35% over budget.

For the next resort, we switched to PVC board with a thin wood-look laminate. It looked identical to the old design but was 100% waterproof. The units cost 18% more upfront but saved 20% in maintenance costs during the first two years. The payback period was under a year, and they haven’t had to replace a single vanity since.

That’s how durability directly supports profitability—and client trust.

Beyond Durability, What Additional Value Can Wholesalers Offer?

For wholesalers like Michael, understanding material performance isn’t just about selling—it’s about winning trust. A diverse material portfolio helps you serve different markets and climates without excess inventory risk.

I once worked with a distributor in Canada who struggled to win high-end condo projects. We developed two targeted product lines: moisture-resistant plywood for regular developments and PVC-core vanities for coastal projects.

This change transformed his business. He could walk into developer meetings and say,

“For your coastal project, we’re using PVC core vanities that reduce after-sales maintenance by 40%.”

That sentence alone made him sound like an expert—and he started winning bids.

When you combine material expertise with reliable manufacturing, you’re no longer competing on price. You’re competing on confidence.

What Are the Emerging Trends in Bathroom Vanity Material Innovation?

The future of bathroom furniture is where durability and sustainability meet. Long-lasting products are inherently more eco-friendly—they reduce waste and energy used for replacements.

I’m constantly testing new materials that meet both performance and environmental standards. Today, more clients are asking for FSC-certified wood, CARB-compliant substrates, and low-formaldehyde plywood that meet North American codes. These choices are not just ethical—they’re smart business.

Surface technology is advancing too. Antibacterial and nano-coated finishes are now standard in high-traffic projects, improving scratch resistance and reducing maintenance time.

Another big shift is modular hybrid construction. Some vanities now use a metal frame with clip-in PVC panels. If one part is damaged, you replace just that panel—not the whole unit. It’s sustainable, cost-efficient, and keeps your brand reputation intact.

The next wave of successful wholesalers will be those who embrace these innovations early.

Conclusion — Durability as a Lasting Advantage

After ten years in this industry, one truth stands out: the most competitive vanities aren’t the trendiest—they’re the ones built to last. Styles fade, but warranty claims and failed installations cost money forever.

If you’re a wholesaler or project supplier, don’t see yourself as just a product source. Be a trusted advisor. Help your clients understand why the right material—matched to the environment—creates real, sustainable profit.

Start every conversation with this question:

“Will this material survive where it will live?”

That mindset builds stronger brands, longer partnerships, and a business that thrives on reputation—not discounts.

This article is a part of our Custom Bathroom Vanity for B2B Project Series. Explore the main guide: Building Competitive Edge: Why Custom Bathroom Vanities Dominate the B2B Market.

About Our Work

At George, we specialize in helping B2B partners like Michael select the right materials for every environment—from humid coastal resorts to high-traffic public spaces. We run humidity and edge-sealing tests, offer flexible MOQ policies, and ensure stable lead times for every order.

If you’re ready to build smarter—not cheaper—let’s design vanities that perform beautifully and endure for years.

Build Better with George

From eco-friendly sourcing to final installation guidance, we are your one-stop manufacturer for hospitality bathroom projects.

Get a free quote specifically tailored to your project specs today.