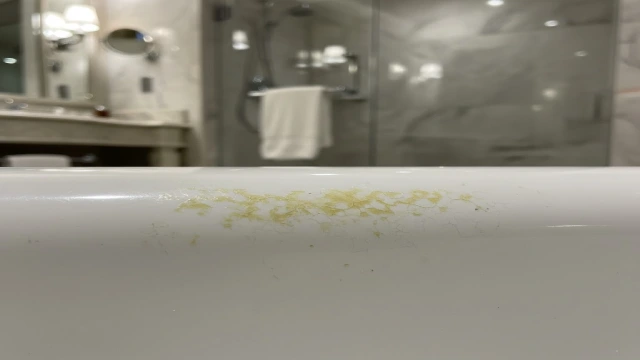

Many hotel project managers and renovation leads face the same persistent frustration: a bathtub that appears yellowed even after rigorous cleaning bathtub routines. In my decade-long experience inspecting hundreds of properties worldwide—from boutique hotels in Europe to massive luxury developments in the Middle East—hotel bathtub yellowing often surprises managers because the causes are rarely related to cleanliness alone.

Understanding why do bathtubs turn yellow is essential for managing maintenance budgets, protecting CAPEX, and preserving the long-term value of your bathroom assets. If you notice a golden or dingy hue on your fixtures, “scrubbing harder” is likely the worst thing you can do.

My name is Helen. Over the past ten years, I’ve walked through countless hotel bathrooms with project managers and FF&E teams, analyzing why certain fixtures fail years before their expected lifecycle. Time and again, I’ve seen that “cleaning harder” only worsens hotel bathtub yellowing, especially in high-traffic rooms. To protect your property and reduce unnecessary maintenance costs, we must look at the problem from an engineering and material perspective.

Table of Contents

Why Yellowing Becomes a Real Problem for Hotel Operations?

What starts as a minor cosmetic issue quickly evolves into a significant operational risk. For a project lead, persistent hotel bathtub yellowing is a red flag that impacts several key performance indicators:

Guest Perception & Trust: Yellowed tubs signal poor hygiene to a guest, even if the room is clinically spotless.

Online Reputation: High-definition photos of a stained hotel hot tub on TripAdvisor can amplify negative impressions and drive away future bookings.

Labor Efficiency: Housekeeping teams spend more man-hours cleaning bathtub surfaces, yet the discoloration persists, leading to wasted labor and lower productivity.

Chemical Consumption: Management often resorts to stronger acids or bleaches that may actually worsen the surface damage.

CAPEX & ROI: Premature resurfacing or total replacement disrupts room availability and directly impacts your long-term Return on Investment.

In short: Persistent hotel bathtub yellowing affects operations, guest satisfaction, and maintenance costs. It is not just a cleaning failure; it is a reputational and financial burden that complicates your overall asset management strategy.

The Root Causes: Why Do Bathtubs Turn Yellow?

To manage your bathroom assets effectively, we must move beyond the surface. Through years of project audits, I have identified four primary drivers of this discoloration.

1. Material Aging and Surface Degradation

Many hotel bathtubs yellow because of material aging at the molecular level. In my experience, luxury properties that opt for lower-density resins or thin gel coats often see oxidation within just 24 months. These materials react to oxygen and ambient light, causing the bright white pigment to shift toward ivory or yellow.

Key Insight: Once oxidation begins, cleaning bathtub surfaces aggressively will not restore whiteness. This underscores the importance of specifying high-density, UV-resistant materials during the initial procurement to protect your asset’s lifecycle.

2. Water Quality and Mineral Deposits

Regional water chemistry plays a silent but decisive role. I’ve noticed that properties in regions with high iron or “hard” water suffer from hotel bathtub yellowing much faster. Calcium and magnesium react with organic soap fats to create a stubborn film. In a high-usage hotel hot tub, the heat accelerates the bonding of these minerals to the surface.

Key Insight: This is a regional factor that dictates maintenance costs; failing to account for local water hardness can lead to permanent mineral bonding that mimics chemical aging.

3. Chemical Reactions from Cleaning Protocols

I often find that the quest for a sterile environment actually destroys the fixture’s finish. From what I’ve observed in the field, using high-alkaline or abrasive cleaners for cleaning bathtub surfaces strips away the protective topcoat. This increases the material’s porosity, making it easier for dirt and minerals to anchor themselves permanently.

Key Insight: Aggressive cleaning protocols increase CAPEX by “etching” the surface, ensuring the yellowing returns faster and deeper in the next cycle.

4. High Usage Intensity and Biofilm Formation

A hotel bathtub undergoes “thermal cycling”—rapid heating and cooling—far more often than a residential tub. This constant stress, combined with the high humidity of a hotel environment, creates the perfect breeding ground for biofilm. These microscopic bacterial colonies often manifest as a persistent yellow or pinkish slime that anchors in the pores of the material.

Key Insight: Asset management planning must account for occupancy-driven stress; high-traffic environments require non-porous materials to prevent biofilm anchoring.

Yellowing is rarely an isolated issue. In hotel environments, discoloration is often just one visible symptom of broader bathtub cleaning and maintenance problems that repeat across properties.

For a comprehensive look at why hotel bathtub cleaning problems keep happening—and how hotels can fix them at the source, read our pillar guide here: Why Hotel Bathtub Cleaning Problems Keep Happening (and How to Fix Them)

Why Cleaning Alone Cannot Solve Yellowing?

Project leads often ask me, “Helen, if we use better chemicals, can we fix this?” I always use this analogy: think of an old white cotton T-shirt. You can wash it ten times with the strongest detergent, but if the fibers have oxidized and the minerals have bonded to the fabric over five years, it will never be “optical white” again.

From an asset-management perspective, hotel bathtub yellowing is a material performance issue, not a hygiene failure. When you apply abrasive tools or harsh acids for cleaning bathtub surfaces, you are essentially sanding down the protective finish, creating micro-scratches that will trap even more yellowing agents. You are treating the symptoms while making the cause worse.

What Is a More Effective Way to Reduce the Risk of Whirlpool Bathtub Yellowing?

Instead of reactive scrubbing, I recommend a structured, three-layer decision framework to handle the yellowing problem and prevent hotel bathtub yellowing from day one.

1. Specification-Level Decisions (Before Installation)

The battle against yellowing is won during the FF&E phase. Based on my data, investing 20% more upfront in high-quality materials can save up to 200% in CAPEX over five years by avoiding premature replacements.

Material Density: Prioritize non-porous materials (like high-grade acrylic or solid surface).

Chemical Resistance: Ensure materials are certified to withstand hotel-grade disinfectants.

UV Stability: Specify high oxidation resistance to ensure long-term color retention.

2. Operational Control (During Daily Use)

Water Testing: If your region has hard water, consider building-wide softening systems to protect your hotel hot tub assets.

Standardized SOPs: Use pH-neutral cleaners for cleaning bathtub surfaces to remove soap scum without stripping the protective layer.

3. Asset Management & Monitoring

Regular Inspections: Train staff to identify mineral buildup early, before it bonds.

Early-Stage Descaling: Use professional-grade, mild descalers quarterly to maintain surface integrity.

Conclusion: Solving Yellowing Starts with the Root Cause

After a decade in the industry, it’s clear: hotel bathtub yellowing results from material, water, chemical, and usage factors—not a lack of effort from your housekeeping team.

If you want to avoid repeated maintenance costs or premature replacements, reviewing your material specifications and cleaning protocols now can save significant CAPEX later. Truly understanding why do bathtubs turn yellow is the first step toward building a more durable, guest-ready property.

For a systematic approach to hotel bathtub challenges, see our full guide: Why Hotel Bathtub Cleaning Problems Keep Happening (and How to Fix Them).

Contact Us today for a brief consultation to review your hotel bathtub specifications and cleaning protocols. I can help you prevent unnecessary CAPEX on future projects and ensure your tubs remain brilliant for years. Would you like me to evaluate your current specifications for your next project?

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼