Are you worried about bathroom vanities failing too soon in your large project? Poor material choices can quickly destroy your budget and reputation.

For long-term use in bulk projects, I recommend materials that balance high durability, moisture resistance, and minimal maintenance, like solid wood cabinets with quartz or sintered stone countertops, as they reduce lifecycle costs and ensure guest satisfaction.

Selecting the right materials for bathroom vanities in a large-scale project, like a hotel or resort, is not just a design choice; it is a critical business decision. I want to share my factory and trading experience with you so you can avoid costly mistakes and get the best value for your investment.

Table of Contents

Why Is Bathroom Vanity Material Selection Crucial for Bulk Projects?

Do low-quality materials threaten your project’s timeline and budget? Cheap vanities can cause massive maintenance headaches later.

Selecting durable vanity materials is vital for bulk projects because it directly impacts lifecycle costs, reduces future maintenance, and ensures a consistent, high-quality guest experience across many rooms.

When I worked in the factory, I saw how material failure in bulk orders created huge long-term problems. The selection is key for several reasons:

- Durability and Longevity: Materials must withstand constant moisture, temperature shifts, and heavy use.

- Maintenance Costs: Durable materials mean less need for costly repairs and replacement parts.

- Consistency: Every unit must look and perform the same to maintain brand standards.

- Guest Experience: Vanities that quickly look worn or break reflect poorly on the property.

I learned early on that saving a small amount on materials now always costs a lot more later, especially in hotel projects where units see constant use. For a Hotel Procurement Manager like Emma, minimizing in-service failures is a top priority, because that directly affects guest satisfaction and room availability. She needs case studies and long-term supply guarantees, which only high-quality materials can truly support. Material choice affects everything from installation ease to the cost of a decade of maintenance. We must think beyond the initial purchase price.

For example, a lower-grade particle board vanity might save 10% on the initial cost, but if it swells and warps after two years due to a plumbing leak, replacing it and the associated labor will cost many times that 10% saving. This makes a strong case for investing in materials that can truly last. In my experience, focusing on the total lifecycle cost—the cost to buy, install, maintain, and eventually replace—is the only smart way to make a decision for large projects. Emma and her team need to know that what they install today will still look good and work well five, seven, or even ten years from now. I recommend we look at materials not just for their appearance but for their proven ability to resist moisture, impact, and cleaning chemicals, which are common challenges in high-traffic bathrooms.

What Bathroom Vanity Materials Are Commonly Used in Bulk Projects?

Are you confused by all the material options for large-scale vanities? You need to know which ones are proven to work in bulk.

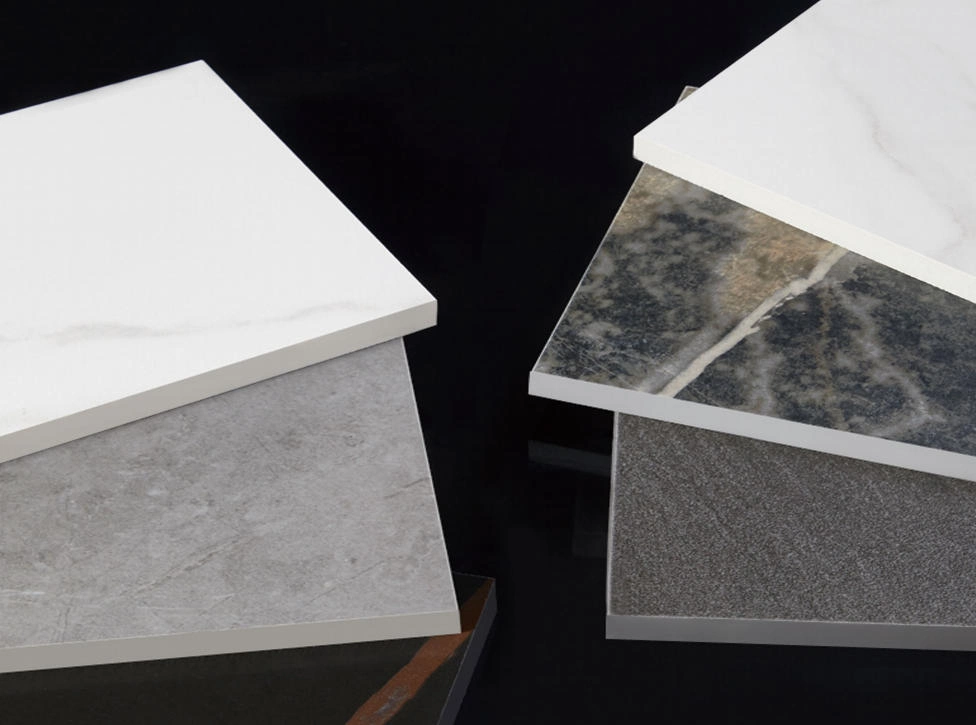

Common materials for bulk project vanities include solid wood (like Oak), plywood, and MDF for the cabinet body, paired with natural stone, engineered stone, or ceramic for the countertop.

When I started my trading company, I saw a few materials dominate the market for large orders. Each one has a distinct profile of cost, durability, and maintenance:

- Cabinet Bodies: Solid Wood, Plywood, MDF (Medium-Density Fiberboard), and Particle Board are the main options.

- Countertops: Natural Stone (Granite, Marble), Engineered Stone (Quartz), Sintered Stone, and Ceramic.

- Sinks/Basins: Ceramic, Resin, or Stainless Steel.

The material you select for the cabinet body and the countertop must be compatible and designed for a wet environment. In a hotel setting, the cleaning staff uses strong chemicals daily, and guests may spill water or leave wet towels. My time in the factory taught me that even small defects in a finish or edge banding can let moisture in and start the destruction process. For cabinet bodies, the moisture resistance is the most important factor.

For example, while MDF is the cheapest option, it swells massively if it gets wet, making it a very poor choice for long-term hotel use, despite its lower upfront cost. Plywood is better because the layers resist moisture more effectively than MDF. But for the absolute best durability, solid wood that is properly sealed and finished is still the king. As a procurement expert, Emma needs the guarantee of durability. A simple way I learned to structure this is by comparing the materials based on their properties, which helps in making an informed choice for a high-volume order:

| Material Type | Moisture Resistance | Durability Score (1-5) | Typical Cost Range |

|---|---|---|---|

| Solid Wood | High (if sealed) | 5 | High |

| Plywood | Medium to High | 4 | Medium |

| MDF | Low | 2 | Low |

| Particle Board | Very Low | 1 | Very Low |

I would not recommend Particle Board or MDF for any long-term project. The risk is simply too high for a hotel that needs a 10-year lifespan from its fixtures.

Which Cabinet Body Materials Are Recommended for Bathroom Vanities?

Which cabinet material will truly last through years of hotel use? You need a moisture-resistant body that won’t warp or swell.

I strongly recommend using quality solid wood (like Oak or Teak) or high-grade plywood for the cabinet body in bulk projects, as both offer superior moisture resistance and structural stability for long-term use.

My experience shows a clear hierarchy of quality when it comes to the cabinet body. For bulk projects that require a 10-year lifespan, you must focus on the top tiers:

- Recommended: Solid Wood (e.g., Oak, Teak, Maple) that has been properly kiln-dried and sealed. It offers unmatched strength and longevity.

- Good Option: Plywood (especially marine-grade or multi-layered, 7-ply minimum). It handles moisture better than fiber-based boards.

- Avoid for Long-Term: MDF and Particle Board. The high moisture in a bathroom, coupled with cleaning chemicals, means these materials break down too fast.

When I was running my own trading company, I advised all my hotel clients to skip MDF completely. The small cost saving is never worth the risk of mass failure. Emma, as a Hotel Procurement Manager, needs to focus on long-term durability to avoid constant replacements. The best cabinet bodies are made of solid wood because wood naturally resists swelling if properly finished. I have seen solid oak vanities last for decades in high-end hotels. However, solid wood requires a higher initial investment and must have an excellent waterproof finish (like a multi-layer polyurethane or UV coating) to perform well. Plywood is a fantastic middle ground; its cross-grain construction limits warping. It is essential to ensure the edges are perfectly sealed with waterproof edge banding to prevent any water penetration. If water gets in, even high-grade plywood can delaminate. The quality of the finish is just as important as the material itself.

A poor paint job on solid wood is worse than a good laminate on high-quality plywood. The finish must be chemically resistant to stand up to the strong cleaning agents used in commercial settings. I always stress the importance of a thick, uniform, and fully cured finish that acts as a true moisture barrier, providing the peace of mind Emma needs for a multi-property contract. I would suggest asking suppliers for specific test data on the moisture absorption rates and chemical resistance of the finish used on their products before signing a bulk contract.

Which Countertop Materials Are Best for Bathroom Vanities?

What countertop material can truly withstand years of stains and spills in a commercial setting? You need a non-porous and durable surface.

Quartz and Sintered Stone are the best countertop materials for bulk projects because they are non-porous, highly resistant to stains, heat, and scratches, and require almost zero maintenance compared to natural stone.

The countertop is the hardest-working part of the vanity; it must endure water, heat from styling tools, and all sorts of spilled products. My factory insights strongly favor engineered over natural materials for sheer consistency and low maintenance:

- Top Choice: Quartz (Engineered Stone). Extremely hard, non-porous, and perfectly consistent across hundreds of units.

- Rising Star: Sintered Stone (e.g., Neolith, Dekton). Offers unmatched durability, is fully non-porous, and is UV-resistant.

- Good Budget Option: Ceramic. Very durable surface, but limited to smaller tops and is prone to chipping on the edges.

- Avoid for Bulk: Natural Marble. Beautiful, but porous, stains easily, and requires constant re-sealing, leading to high maintenance costs.

My experience has shown that in high-volume, high-traffic projects, the goal is to make the material virtually indestructible and maintenance-free. This is where quartz and sintered stone truly shine. My initial insight pointed to quartz for a reason: it checks every box for a hotel procurement manager like Emma. Unlike natural stone like marble or granite, quartz is manufactured, making it perfectly non-porous. This means a spilled glass of wine or makeup remover will not soak in and create a permanent stain.

For a hotel, this single feature is a massive win, saving time and money on stain removal and replacement. Sintered stone takes it even further; it is created by compacting natural materials under extreme heat and pressure, making it one of the hardest and most resistant materials available—it can even withstand direct contact with hot styling tools without damage. I would only recommend natural marble or granite for the most high-end, bespoke suites where the cost of regular maintenance is acceptable. In the vast majority of hotel rooms, consistency and low lifecycle cost are more important. The small extra cost for quartz over a cheaper granite is immediately offset by eliminating the need for regular sealing and reducing the risk of permanent staining. This certainty and low maintenance profile are the very things Emma needs to meet her quality and cost control goals. I always advise my clients to focus on the long-term value: an installed quartz vanity means one less thing the hotel staff has to worry about.

How to Choose the Best Bathroom Vanity Materials for Bulk Projects?

Are you ready to finalize your bulk vanity order? You need a clear process to select the optimal, long-lasting materials.

To choose the best materials, you must balance the project’s budget with the required durability (aim for a 10-year lifespan), focusing on moisture resistance, ease of cleaning, and the supplier’s consistency for large volumes.

Choosing the right material is a strategic process. Based on all my years in the industry, I use three main filters when advising clients on bulk projects:

- Project Lifespan and Budget: Match the material’s durability to the project’s expected life (e.g., a 10-year hotel life needs solid wood/plywood and quartz).

- Moisture and Maintenance Profile: Select non-porous, fully sealed materials that resist water damage and require minimal routine maintenance.

- Supplier Consistency and Service: Ensure the factory can deliver hundreds of units with identical color and finish quality and provide strong post-sale service.

For large projects, the final choice must meet the procurement manager’s (like Emma’s) need for a reliable, low-risk product. My insight, which favors solid wood cabinets and quartz countertops, comes from this focus on minimizing long-term failure and maximizing guest experience. Emma’s main challenge is coordinating deliveries and ensuring consistent finishes across all rooms. This means the material chosen must be easy for the factory to process consistently and must be available in large, stable supply. Natural materials like marble can vary wildly in color and veining from one batch to the next, which makes consistency a nightmare for a hotel with hundreds of rooms. Engineered materials like quartz solve this problem entirely because the color and pattern are controlled in the factory. When I help a client, I always create a risk assessment based on the material choice.

For example, the risk of a plywood cabinet warping is low, but the risk of a particle board cabinet warping is extremely high. By eliminating high-risk materials, we ensure the project stays on schedule and avoids costly room downtime after installation. The final selection should be based on a material specification that includes not just the type of wood or stone, but also the specific grade, the type of sealant or finish, and a guaranteed consistency tolerance. This level of detail is what guarantees the long-term success of the project.

Conclusion

I recommend solid wood cabinets and quartz countertops for the best long-term value in bulk projects. We share our expertise to help you master your craft and succeed.