Introduction — Why Smart Customization Matters in B2B

I’ve spent over ten years in the custom bathroom vanity industry. I’ve seen the old way: paperwork everywhere, wasted materials, and late deliveries. Today, digital systems replace paperwork, making every stage — from design to delivery — efficient, traceable, and low-waste.

Customization is no longer a luxury; it has become a strategic necessity for wholesalers and developers. Clients now expect tailored dimensions, material combinations, and sustainable finishes that meet diverse project requirements. Traditional methods create bottlenecks, longer lead times, and unpredictable costs.

From my experience, smart customization — powered by modular design and digital manufacturing — is the key to achieving both flexibility and supply chain efficiency.

Table of Contents

Market Background — Complexity is Reshaping Supply Chains

The bathroom vanity industry is undergoing a structural shift. Fortune Business Insights predicts the global custom furniture market will exceed $65 billion by 2030, growing over 7% annually. McKinsey and Deloitte report that supply chain responsiveness and flexible manufacturing are now top priorities for B2B buyers.

Clients like Alice, a wholesaler managing hotel and residential projects, face tight timelines, diverse specifications, and strict ESG requirements. The need for reliable, customizable, and eco-friendly solutions is now the standard.

Traditional workflows — manual design confirmations, fragmented supply chains, and isolated production steps — cannot keep pace. Smart customization, integrated with digital systems, bridges flexibility and operational efficiency.

B2B Pain Points — Where Traditional Customization Falls Short

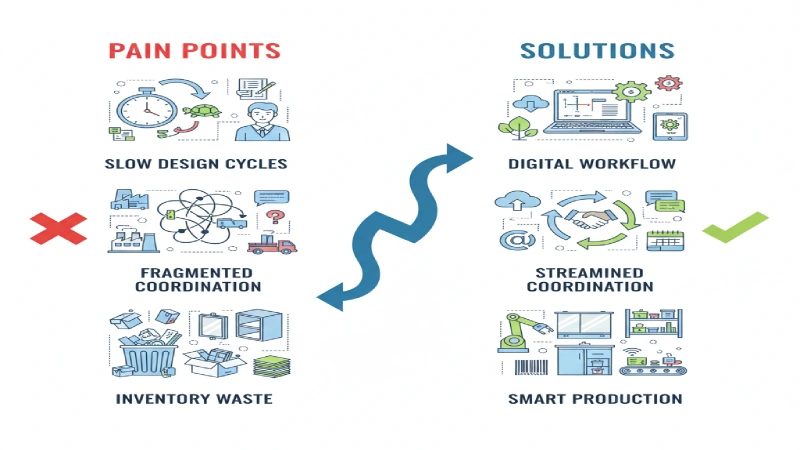

Working with wholesalers and developers, I see three recurring challenges:

Key Operational Challenges

Inefficient Quoting & Design Cycles

Manual approvals slow project turnover, increase costs, and reduce competitiveness. Every extra week delays revenue and weakens bidding power.

Fragmented Supply Chain Coordination

Custom projects often involve multiple suppliers. Inconsistent data sharing leads to reactive problem-solving rather than proactive planning.

Inventory Waste & Demand Risk

McKinsey reports that companies using digital forecasting and smart production cut inventory costs by an average of 28%.

Expert Pick: Explore unified custom solutions. View Collection →

These challenges highlight that offering more product options isn’t enough; customization must align with operational efficiency.

Smart Customization — Faster, Flexible, Low-Waste

Smart customization solves these problems through modular design, digital workflows, and data-driven production.

1. Modular Design Systems

Instead of starting from scratch for each project, modular components allow scalable personalization. For one distributor, modular assembly cut production time by 40% while offering a wide range of unique looks.

2. Digital-to-Manufacturing Workflow

AI-generated drawings feed directly into automatic material optimization and real-time production scheduling. Deloitte reports digital workflows reduce delivery time by 35–50%, ensuring clients meet tight timelines reliably.

3. Low-Waste, Data-Driven Production

Smart cutting and predictive nesting software maximize material utilization. On a large residential project, AI optimization achieved 97% material yield, reducing total project costs by 12% and minimizing environmental impact.

Result: Smart customization reduces errors, waste, and rework, creating measurable business value while supporting ESG goals.

Strengthening B2B Partnerships

Intelligent customization transforms supplier relationships into strategic collaborations:

Predictable Benefits of Digital Systems

Predictable Lead Times

Digital systems remove guesswork, allowing reliable delivery promises.

Transparent Cost Control

Every dollar is tracked, with no surprises or wasted materials.

Stronger Product Differentiation

Unique vanities can be offered without the high risk or cost of traditional custom work.

Integrated platforms allow data sharing from design to inventory forecasts, turning the supply chain into a collaborative ecosystem. Wholesalers gain confidence in order accuracy, while manufacturers benefit from repeat contracts and joint product development opportunities.

PwC’s 2024 B2B Buyer Study found that 72% of buyers prefer suppliers offering digital transparency and flexible customization — exactly what smart customization delivers.

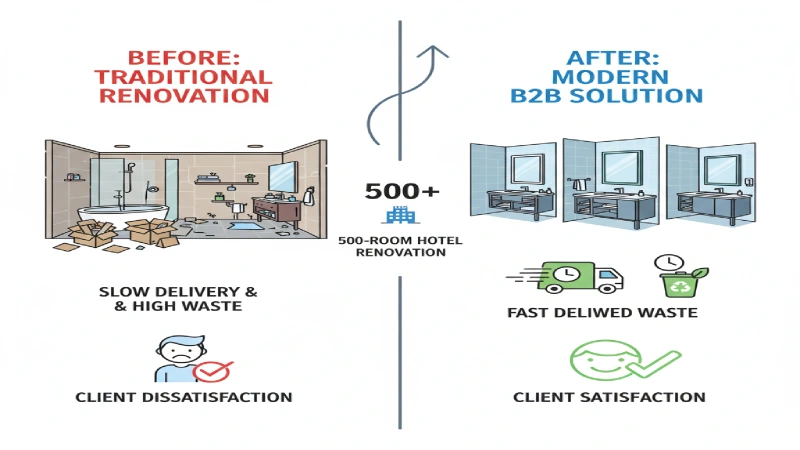

Case Study — Large Hospitality Project

Alice, a client managing a 500-room hotel renovation, adopted our intelligent customization workflow. Results:

Measurable Results of Digital & Smart Production

Faster Design Approval

Design approval time reduced by 60% using digital sign-off and AI-generated drawings.

Reduced Production Waste

Production waste decreased by 40%, saving material costs and lowering environmental impact.

Higher Client Satisfaction

Client satisfaction and repeat business increased significantly, thanks to on-time delivery of high-quality, customized vanities.

Project Snapshot: 500-Room Hotel

The Pain Point

Tight timeline threatened opening; complex custom specs delayed approvals.

Our Solution

AI-driven modular design & digital supply chain integration.

The Result

60% faster approval, 40% less waste, on-time delivery.

This demonstrates that smart customization transforms B2B projects from procurement headaches into seamless, value-driven collaborations.

Conclusion — Build Your Next-Generation Competitive Edge

The B2B bathroom vanity market is entering a digital, intelligent, and collaborative era. Wholesalers and developers no longer have to choose between tailored products and reliable timelines.

By embracing smart customization and digital supply chains, manufacturers can:

- Streamline production, reduce waste, and cut costs

- Deliver highly differentiated, durable, and sustainable products

- Strengthen strategic partnerships and ensure repeat business

At George Build Shop, we help B2B partners transform their supply chains — making them faster, smarter, and greener. Contact us to start your smart customization journey and redefine what custom manufacturing means for the modern era.

To dive deeper into our custom bathroom vanity series guide: Building Competitive Edge: Why Custom Bathroom Vanities Dominate the B2B Market.

Ready to Upgrade Your Hotel's Bathroom Experience?

Don't let supply chain complexities delay your opening date. Partner with George Build Shop for a seamless, factory-direct experience.

Get a free quote and 3D rendering proposal for your project within 24 hours. Fill out the form below to get started: