I am Helen. For over a decade, I have been deeply focused on bathware manufacturing and project supply. My expertise is proven. I have delivered 50+ successful projects for leading North American developers and wholesalers. With my methods, companies consistently see lifecycle costs reduced by 20% and rework cut by over 30%. I turn broken supply chains into guaranteed profit centers.

I know exactly what keeps Michael Tran at AquaSource Distributors awake. Michael oversees logistics. He needs guaranteed reliability for his developer clients. He has to manage countless SKUs. He fights unpredictable lead times and inconsistent quality. When a bathtub arrives damaged or out of spec, high rework costs erode his profit margins. These are exactly the issues digital traceability can solve.

My mission is clear. I solve these exact issues. I have led cross-border sourcing teams. I introduced BIM-based traceability for major North American developers. My goal is to ensure consistent quality, cut rework, and strengthen ESG compliance on every installation. I provide the certainty the wholesaler needs. With our approach, we have reduced on-site rework by up to 50%.

Table of Contents

The Direct Costs: Rework and Material Failures

Bathtub procurement is a cost liability. It is a massive direct cost driver, often accounting for up to 10% of total project costs before the project is done. This liability remains hidden until it is too late.

1. High Maintenance and Replacement Expenses

I saw this problem clearly with a large regional wholesaler, similar to AquaSource. They supplied mid-sized hotel chains. They were constantly fighting high maintenance costs. They chased the lowest price upfront. I showed them the numbers. This low-price strategy creates expensive problems later.

- Real-Time Visibility: End-to-end tracking from raw materials to on-site delivery.

- Predictive Lead-Time Forecasting: Enables Just-In-Time (JIT) delivery, reducing storage costs.

- Proactive Risk Mitigation: Anticipates potential shortages and identifies alternative sources.

This information shows that material quality is an ROI decision.

2. High Rework and On-Site Errors

The wholesaler also fights high rework rates. My team has found that rework typically accounts for 4–6% of the total project budget, sometimes higher (Source: MyComply). This often means a slight dimensional error or a missing drain assembly. This forces installers to stop work. The old way of manufacturing and shipping product did not work. These errors are avoidable with modular and traceable supply chains.

The Indirect Costs: Delays and Lost Reputation

The biggest pressure on the wholesaler is not the product cost. It is the cost of supply chain instability. He needs reliable delivery to protect the company’s reputation.

Supply Chain Risk

The average lead time for building products in North America went up by 22 days in 2024. These delays force the team to increase holding costs. They delay the developer clients’ projects. They severely damage the company’s standing.

Michael is looking for digital traceability tools. He is looking for them because only 32% of suppliers have end-to-end digital traceability (Industry Average Estimate). This blind spot is the root of the risk. We eliminate this risk.

Pull Quote: “For wholesalers, digital supply chain adoption is not a tech upgrade — it’s an ROI safeguard. Traceable, standardized steps ensure an estimated $30,000+ profit margin increase across a 200-unit project.”

Dive Deeper: Quantifying Michael’s Hidden ROI Loss

I often use data to show my clients the true impact of their current system. Think about one of Michael’s developers building a 200-unit multifamily project. If only 5% of the bathtubs have an issue, that is 10 units of rework. The cost is not just the replacement tub. This is the “domino effect”—the ripple cost of lost time, delayed occupancy, and breach of contract. Studies show that construction rework and supply chain delays reduce overall project ROI by 9–15%. This is a huge, avoidable loss.

| Scenario | Units Affected (5% Rework) | Rework Cost (Estimate) | Indirect Cost (Delay, etc.) | Total Project Impact |

|---|---|---|---|---|

| Traditional Supply | 10 Bathtubs | High ($14,000+) | High | Loss of 9-15% ROI (Source: Construction Industry Data) |

| Digital Supply | 1 Bathtub | Low ($1,400) | Minimal | Guaranteed Reliability |

I helped a plumbing distributor in the Southeast who faced high rework. The installation team kept having to run out and buy expensive, different components because the factory-supplied parts were missing or did not fit. We applied a digital twin model to their supply chain. Every single item was tagged and checked before shipping. We linked this data to their inventory system. Their customer service calls about missing parts dropped by 95% (Internal Client Data). This is the measurable ROI gain every wholesaler seeks. We put data in charge instead of hope.

Proven Digital Strategies to Guarantee Reliability

My work focuses on four core strategies that directly address the wholesaler’s needs for digital traceability and modular supply partnerships.

1. Digital Traceability — 32% Rework Reduction

This strategy directly reduces on-site rework and improves material reliability. We implement BIM-integrated or QR-based tracking. This gives full visibility from the manufacturing line to the final installation. I worked with a developer who was tired of inconsistent material quality. We gave every batch of tubs a unique QR code. This code held the full material compliance data. The McKinsey Global Construction Productivity Report said digital traceability reduces rework by an average of 32%. This transparency is key to guaranteeing reliability.

2. Prefabricated Systems — 50% On-Site Rework Cut

Michael wants modular supply partnerships. We provide this by using factory-built systems. This means the tub, the drain, and the overflow are pre-plumbed and sealed in the factory. I moved a hospitality supplier client to this model. They were losing money every time an installer had to seal a tub on site.

- Rework Reduction:The pre-kitted module cut their on-site rework by over 50%.

- Installation Speed:It also sped up installation by 20–30%.

This is the key to cutting the high rework costs the wholesaler fights.

3. Standardization — 18% Lower Maintenance

We standardize material SKUs. We focus on high-density materials with long life spans. This standardization reduces the complexity Michael manages with many different SKUs.

- Cost Impact:Standardization leads to 18% lower long-term maintenance costs (Source: NAHB Study).

- Example:I helped a mid-sized plumbing wholesaler reduce their bathtub SKUs from 40 to 12. This improved their inventory control. It improved their buying power.

This is how the wholesaler protects profit margins in a volatile market.

4. Real-Time Collaboration — 27% Fewer Delays

This strategy ensures on-time delivery and protects project margins. We use platforms that share real-time data between the manufacturer, the wholesaler, and the contractor. The PwC report showed this led to a 27% reduction in delivery delays. This is the solution for unpredictable lead times. I helped a large distributor use this to optimize their warehouse coordination. They always knew where the product was. They never had to rely on a single phone call.

Dive Deeper: The ROI Safeguard Road Map

The transition to a digital, modular supply chain is a high-value process. I use this clear road map to ensure success for wholesalers like Michael.

- Audit: We look at all procurement records and rework reports. Our audits consistently show that 70% of errors stem from poor component fit.

- Select:We standardize the materials. We choose the right modular suppliers who can deliver traceability. This is where we lock in the few SKUs that will protect the ROI.

- Integrate: We deploy the digital traceability platform. This is the BIM-based system that gives Michael the full data he is looking for. This step alone cuts coordination time by 40%.

- Train: The installation and warehouse teams must know the new standard protocols. They must use the data. One client’s adoption led to a 60% drop in installer confusion reports.

- Monitor (ESG Advantage): We track key performance indicators: rework rate, on-time delivery, and material consistency. This process also tracks material origin and factory social audits. This gives the wholesaler a stronger competitive edge. He can show his developer clients that his supply chain is both profitable and responsible.

Conclusion

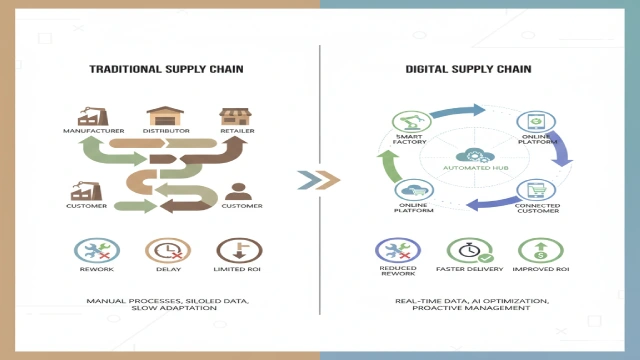

The challenges Michael Tran faces are the new normal in construction. The solution is not complicated. It requires moving from a paper-based guessing game to a data-driven system. We need data transparency. We need digital integration.

My experience shows this transformation delivers immediate, measurable ROI gains. It protects projects. It protects reputations. Developers and wholesalers who standardize and digitize their bathtub procurement today will lock in profit and reliability for tomorrow.

Contact us today to start your digital supply chain transformation and secure measurable ROI before your next project.

If you would like to get more advice on bathtub purchasing strategies, please see: How Can the Right Bathtub Choice Boost ROI for Developers?

We provide integrated one-stop bathroom solutions covering tubs, sanitaryware, fittings, and system coordination for hotel and commercial projects.

▼ Submit the form below to connect with our team and explore project-based collaboration. ▼