Are your inventory costs too high? Is your stock outdated before it even sells? The North American market demands flexibility now.

Custom bathroom vanities, especially with modular designs, help distributors stay competitive by allowing faster response to design trends, reducing excess inventory risk, and meeting the diverse needs of both retail and project clients without massive fixed stock.

I have worked with distributors like Samantha for over a decade. I have seen the market change. What worked in the past with standard, one-size-fits-all vanities is simply not working today. The buying landscape has changed too much, and if you are not adaptable, you will lose sales to competitors who are. We must adapt to survive.

Table of Contents

Why are standard bathroom vanities failing distributors today?

Your warehouse is full of vanities that sit there for too long. You are losing capital and market share.

Standard products fail distributors because they create large, inflexible SKUs that are hard to sell when trends change. They increase inventory risk, tie up capital, and cannot easily meet the varied specifications needed for hotel or large construction projects.

I recently spoke with Samantha, the Operations Director at one of my largest clients. Her main problem was capital. She had a huge investment in about 50 standard models. When the popular finish shifted from dark walnut to natural oak almost overnight, her entire dark walnut stock became a liability. Standard vanities force a choice between high stock risk and lost sales. You cannot stock everything, but if you do not have the right item, a competitor wins the bid. This failure is a direct result of old manufacturing models. They send you a fixed product, and you have to hope the market agrees. This puts the entire risk on you, the distributor. My business is built on removing that risk. We need a system that lets you adjust finishes, sizes, and tops without ordering a completely new, fixed SKU.

The Distributor’s Inventory Dilemma

1. Inventory Risk

Standard Vanity Model: High; tied to large, fixed SKUs.

Flexible Custom Model: Low; stock only essential modules/parts.

2. Market Responsiveness

Standard Vanity Model: Slow; months to clear old stock and order new trends.

Flexible Custom Model: Fast; components can be quickly combined for new trends.

3. Project Customization

Standard Vanity Model: Extremely difficult or impossible.

Flexible Custom Model: Simple; combine standard components into a custom solution.

4. Capital Efficiency

Standard Vanity Model: Poor; capital is tied up for long periods.

Flexible Custom Model: Excellent; faster stock turnover, less capital tied up.

What key market trends demand greater flexibility from my suppliers?

Customers now want their vanities to look unique. This demand for personalization is a major market force.

Two key trends demand flexibility: the rise of personalized design in the residential market and the specific, high-volume requirements of hospitality and multi-family projects. Distributors must offer customizable options to satisfy these diverse client needs and secure project bids.

The North American market today is not about a few popular styles; it is about endless variations. Think about a homeowner renovating a bathroom. They want a specific size, a unique hardware finish, and a countertop material that matches the shower tile. If you, the distributor, can only offer three fixed sizes, you lose that sale immediately. On the project side, the demands are even stricter. A hotel chain might need 200 vanities, but they must all meet specific ADA compliance, a precise laminate color, and a certain basin type. Samantha shared a story with me where she lost a major hotel contract simply because her supplier could not swap the standard vanity’s door hinges for soft-close ones at scale. The trend is moving from “What do you have?” to “Can you make this for me?” This shift is why traditional fixed inventory is becoming obsolete. We need a manufacturing partner that can treat a vanity not as a single product, but as a collection of interchangeable, high-quality components.

Market Demands by Segment

1. Residential Retail

Primary Need: Design personalization, unique finishes, specific sizing.

Distributor Challenge: High SKU count required, high risk of carrying wrong inventory.

2. Hospitality / Hotels

Primary Need: Large volume, strict specifications (ADA, safety, durability), fast lead times.

Distributor Challenge: Standard product inflexibility, loss of project bids due to small deviations.

3. Multi-Family Projects

Primary Need: Cost efficiency, standardized look across units, custom material choice for longevity.

Distributor Challenge: Difficulty balancing cost-efficiency with quality and specification needs.

How can modular customization solve my inventory and market problems?

You need high customization without high risk. Modular design is the answer you have been searching for.

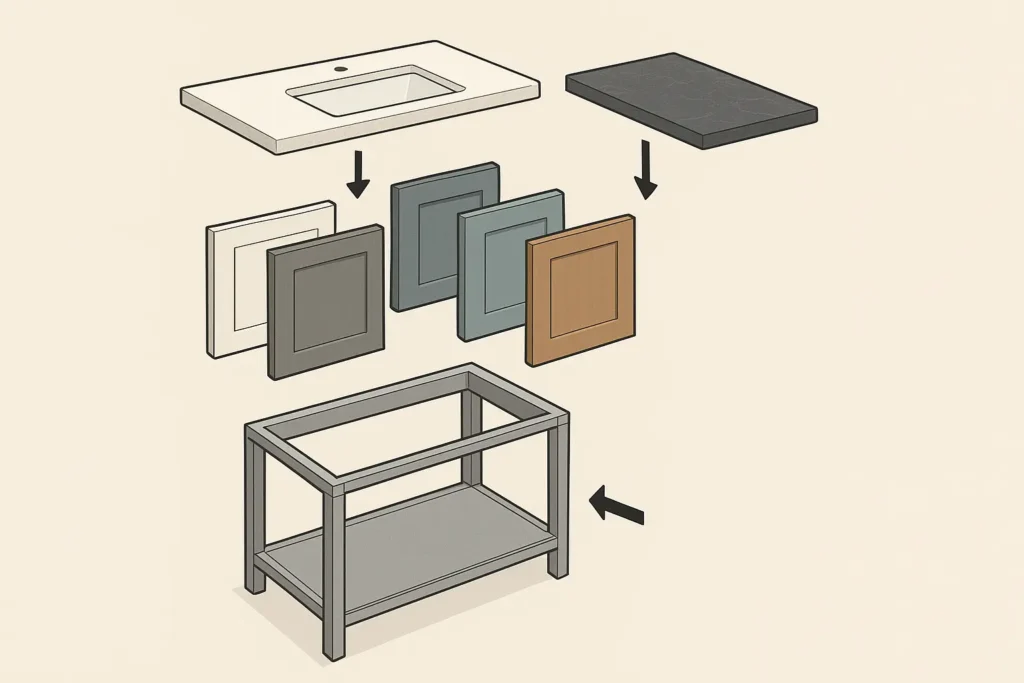

Modular customization solves inventory and market problems by breaking down the vanity into interchangeable components—the base, doors, tops, and hardware. Distributors only need to stock fewer core parts, which they can assemble into dozens of configurations, drastically cutting storage costs and allowing on-demand trend adjustments.

This is where I focus all my efforts at George. My insight, which I constantly share with my partners like Samantha, is that modular customization is the key to grasp the North America Custom Bathroom Vanity Market. It is a simple idea, but powerful. Instead of stocking 100 finished 48-inch vanities in 10 colors with 10 tops, you stock 10 base frames, 10 door styles, and 5 countertop materials. You can then create up to 500 unique finished products from this smaller inventory. This is the difference between having $500,000 tied up in fixed goods and having $100,000 in versatile stock. For Samantha, this meant she could test a new color trend with only a small order of doors instead of a full container of finished units. We work together to identify the most popular core frames and then use my manufacturing capabilities to provide the custom ‘skins’—the doors, drawers, and tops—that quickly change the entire look. It moves your business from a guessing game about future trends to a fast-response assembly system. This is true competitive flexibility.

The Modular Customization Advantage

1. Vanity Base Frame

Inventory Strategy: Stock in common sizes (24", 36", 48", 60").

Flexibility Gain: The stable core; low inventory turnover risk.

2. Doors / Drawer Fronts

Inventory Strategy: Stock in various finishes and styles.

Flexibility Gain: High aesthetic variability; quick trend changes (e.g., swapping Shaker for Slab).

3. Countertops

Inventory Strategy: Stock in 3–5 high-demand quartz/stone options.

Flexibility Gain: Customization for different project tiers (e.g., granite for budget, quartz for luxury).

4. Hardware

Inventory Strategy: Stock a few finishes (matte black, brushed gold).

Flexibility Gain: Easy upgrade path for retail clients without major structural changes.

Can you give me a real-world example of modular customization in action?

You need proof that this strategy actually works. I have a story that shows exactly how we solved a major problem.

A real-world example involves a large distributor who needed to fulfill a multi-family project requiring 300 vanities across five distinct unit types. We used two standard base sizes but customized the cabinet depth, countertop material, and hardware, turning a complex, high-risk order into a profitable, on-time delivery by simply combining pre-approved modular components.

Samantha’s company secured a large multi-family contract, but the client needed five different vanity specifications: a compact ADA-compliant unit, a standard guest unit, and three different master bath units based on the apartment tier. If she used a standard supplier, this would mean ordering five separate production runs, five separate quality checks, and massive minimum order quantities (MOQs) for each. This would be a logistical nightmare. Instead, we worked with my modular system. We decided on two core base frames: a 30-inch and a 60-inch. For the ADA unit, we customized the counter height and the toe-kick. For the different apartment tiers, we kept the base frame the same but changed only three components: a budget laminate top for Tier 1, a mid-grade quartz top for Tier 2, and a unique wood veneer door for the Tier 3 master suites. The efficiency was amazing. Samantha only had to manage two large MOQs (the bases) and smaller, manageable orders for the customized components. The entire project was delivered on time, and her profit margin was protected because there was no leftover, single-use inventory. This example proves that customization does not mean complexity; it means using smart modular design to create endless options from a few core parts.

Project Breakdown: Modular vs. Standard

Total SKUs to Manage

Inventory Risk

Lead Time

Customization Cost

How does using modular custom vanities provide a long-term strategic advantage?

Your goal is not just to survive this year. You need a strategy that guarantees your dominance for years to come.

The strategic advantage of modular custom vanities is future-proofing your business. It establishes your distribution company as a flexible, trend-responsive partner, deepening trust with large clients like developers and retailers, and creating a competitive moat that standard, rigid suppliers simply cannot cross in the long run.

This is the big picture. When Samantha and I started working together, her competition was winning bids because they could offer some customization, even if it was expensive and slow. Now, she is the one winning. The modular approach is not just an inventory trick; it is a sales and marketing advantage. When Samantha meets with a large retailer, she does not pitch fixed products. She presents a “design system.” She can tell them, “We can launch ten new vanity looks for your store in the next quarter just by changing the door finish and hardware, and we can do it without risking high inventory.” This ability to offer high-quality, customized products at scale, without the massive fixed costs, makes her company a strategic partner, not just another supplier. The long-term value comes from client loyalty and the ability to adapt to unforeseen market shifts. Imagine a sudden supply chain disruption in stone—a modular system allows you to instantly swap to a different countertop material with minimal change to the rest of the product, keeping your promises to your clients. This is how you build a lasting, dominant business in 2025.

Strategic Market Benefits

Client Loyalty

Trend Agility

Sustainable Growth

Conclusion

The market demands flexibility, and modular customization is the answer. It slashes inventory risk, boosts trend response, and builds a powerful, long-term competitive edge for your distribution business.

George is always your powerful partner. If you are ready to future-proof your inventory and win more project bids, don’t hesitate to get in touch with us.

Explore our Custom Bathroom Vanity for B2B Project Series: Building Competitive Edge: Why Custom Bathroom Vanities Dominate the B2B Market.