Bathtub design dramatically affects installation time and labour for hotel projects — because it governs how easily tubs can be handled, positioned, plumbed, waterproofed, and tiled across hundreds of rooms. Choosing lightweight, structurally reinforced tubs (or pod-ready bathtubs) with standard plumbing alignment, three-sided flanges, and lift/corridor-friendly dimensions can cut installation labour by 20–40 minutes per room, reduce on-site trades coordination, and avoid costly rework — translating to tens to hundreds of thousands of AUD savings across a large hotel fit-out.

Table of Contents

Introduction — Why This Matters in Australia

In my decade working with hotel developers, builders and procurement teams across Australia, I’ve seen gorgeous specifications derailed by something as simple as a heavy, poorly designed bathtub.

In high-wage markets like Sydney, Melbourne or Brisbane, every extra 10 minutes per bathroom equates to substantial labour costs — and when you’re fitting out hundreds of rooms, small inefficiencies multiply fast.

What many don’t realize is:

Installation inefficiencies often come not from trades or scheduling — but from the bathtub’s design itself.

That’s why bathtub design should be viewed as a construction strategy, not just a procurement choice.

What the Industry Data Says — Prefab Bathrooms & Time / Cost Savings

Although public academic data on “bathtub design → per‑room install time” is limited, the broader trends for prefabricated bathroom pods (including tubs, plumbing, waterproofing, and finishes) clearly show that design and factory-controlled production drastically cut time, labour, and defects:

Prefabricated pods can save up to five working weeks on bathroom construction compared with conventional in-situ methods (Source: Build Offsite).

Modular bathroom installation reduces on-site labour by 20–50% and accelerates project timelines by 30–50% (Source: i2r Modular).

Hotels using prefab bathroom solutions often reach “heads-in-beds” 2–3 months earlier than traditional methods (Source: Hotel Business).

Modular/prefab approaches also significantly reduce punch-list items and defects because on-site trades operate in tight spaces and rework is minimized (Source: Build Offsite).

Interpretation for bathtub design: Even if you don’t adopt full pods, designing bathtubs according to modular/prefab principles (lightweight, standardised, site-friendly) captures many of these benefits.

Installation-Friendly Design Features for High-Density Projects

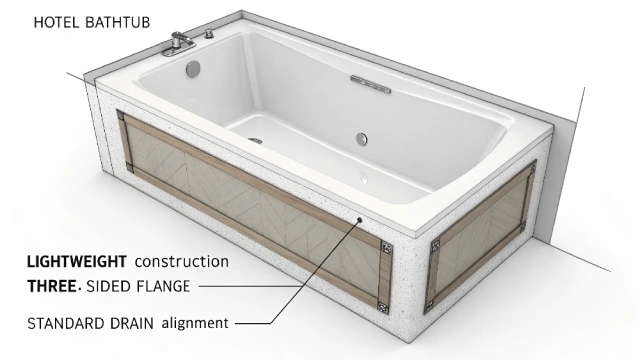

| Design Feature | Impact on Installation Time & Labour | Why It Matters for Hotels / High-Density Projects |

|---|---|---|

| Lightweight Construction (≤ 65 kg) | Easier handling, fewer installers, no mechanical lift needed | Ideal for tight lifts and corridors; reduces labour cost and WHS risk |

| Integrated Base / Adjustable Feet | No site-built framing; fast, precise leveling | Speeds tiling & waterproofing; reduces rework and QA delays |

| Standard Drain & Overflow Alignment | Avoids plumbing conflicts | Allows batch installation across multiple rooms |

| Three-Sided Flange / Tile Lip | Simplifies wall finish & waterproof detailing | Works with plasterboard/tile systems; prevents leaks & defects |

| Lift & Corridor-Friendly Dimensions | No crane or special handling required | Cuts logistics costs and avoids delivery delays |

| Access Panels / Serviceability Features | Maintenance without demolition | Lower lifecycle maintenance cost |

| Tight Dimensional Tolerance & Factory QC | Minimizes on-site corrections | Ensures consistent fit, reduces defects, supports brand standards |

Practical Implementation: What I Advise Hotel Developers & Builders in Australia

Specify “hotel-grade bathtub design” in tender documents

Lightweight ≤ 65 kg, integrated base, standard drain alignment, three-sided flange

Consider partial modular/prefab approach

Even if full pods aren’t used, bathtubs compatible with pod-ready geometry simplify installation

Demonstrated 20–50% reduction in on-site labour hours and faster project delivery (Source: i2r Modular, Build Offsite)

Ensure consistent procurement

Batch orders → less dimensional variation, streamlined maintenance & spare parts

Require supplier shop drawings & QA documentation

Early detection of potential issues → fewer post-installation defects

Plan logistics early

Confirm lift/elevator clearance, corridor width, and site access

Include serviceable access panels

Reduces long-term maintenance costs and room downtime

Why This Matters — Real World Cost & Risk Impact

Prefab bathrooms reduce labour 20–50% and speed schedule 30–50% (Source: i2r Modular)

Faster bathroom fit-out accelerates hotel opening and revenue (Source: Build Offsite)

Less on-site labour, fewer defects → lower risk of delays and variation claims

Designing for installation efficiency protects budget, schedule, and long-term operability.

Final Thoughts

Treat bathtub design as a strategic decision, not a commodity purchase. Proper upfront specification avoids installation pitfalls, saves labour, reduces risk, and ensures smoother project delivery.

I can provide a full Bathtub Specification Template for Australian hotel projects, including dimensions, drain layout, base requirements, lift/corridor clearance checklist, and installation guidelines — saving time and mitigating risk. Contact me to transform your bathtub procurement into a project-saving strategy.

If you want to prevent installation delays, defects, and procurement risks from the very start, read our guide on How Your Hotel Can Avoid Costly Bathtub Problems Before Construction Even Begins.

FAQ

Q1: Does a lightweight or pod-ready bathtub increase material cost?

Yes, slightly — but the added cost is quickly offset by lower labour requirements, faster installation, and earlier room readiness (higher revenue).

Q2: How much time can a 200-room hotel save?

Typically 20–40 minutes per room, which equals ~67–133 labour hours, excluding reductions in rework.

Q3: Is full prefab necessary to gain efficiency?

No. A well-designed bathtub (lightweight, aligned drain, integrated base) captures most of the efficiency gains without full pod construction.

Q4: What risks remain even with optimized bathtub design?

Waterproofing, tiling, and plumbing alignment still require on-site management to avoid leaks and quality defects.

Q5: Which projects benefit most from these design optimizations?

Large hotels, high-rise towers, and high-density developments, where logistics and labour coordination heavily impact timelines and cost.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼