Are you tired of replacing worn-out hotel bathroom countertops that chip, stain, and fail the durability test? I know the struggle.

The best commercial bathroom countertop materials are those that balance durability, low maintenance, and design flexibility, with quartz, granite, solid surface (Corian), porcelain, and marble being the top choices for various project needs.

Choosing the best wood for a bathroom vanity can feel like a gamble when you are ordering hundreds. I have been in the factory and trading sides of this business for years, and I know the headaches of coordinating quality, delivery, and cost. Let’s break down the best choices so you can make a smart, confident decision that lasts.

Table of Contents

Is a Solid Wood Vanity Good for a Bathroom?

Is solid wood really the best choice for a damp bathroom environment? Many buyers struggle with this choice, fearing warping and mold.

Yes, solid wood is great for a bathroom vanity when it is a naturally durable species like oak or teak and is sealed properly. It offers the best structural strength and premium look, providing longevity that outweighs the higher initial cost if maintained well.

Solid wood has several key benefits for a bulk vanity order:

- Premium Look and Feel: It gives a high-end, luxurious finish that guests notice.

- Structural Durability: A solid wood frame is much stronger and resists damage better than engineered materials.

- Refinishing Potential: Unlike veneers, solid wood can be sanded and refinished to fix deep scratches, extending its life.

- Long-Term Value: The initial higher cost is often offset by its long lifespan and reduced replacement frequency.

You might hear people talk about solid wood warping, and that can happen with the wrong wood or bad manufacturing. The secret is the preparation and the finishing. Good solid wood for vanities is kiln-dried to a specific moisture content to prevent movement after installation. It needs a multi-layer, high-quality polyurethane finish to seal all surfaces completely. For a hotel buyer like Emma, it’s about checking the supplier’s process. I always recommend asking for the kiln-drying specs and the details of the finishing process. This focus on process ensures the natural durability of solid wood is locked in.

| Wood Type | Durability Grade | Moisture Resistance | Bulk Cost (Relative) |

|---|---|---|---|

| Oak | Excellent | Very Good | Medium |

| Teak | Superior | Superior | High |

| Plywood | Good | Good (if marine grade) | Low |

What Are the Top Wood Materials for Premium Vanities?

You need a vanity that screams luxury but still stands up to daily hotel use. What materials deliver high-end appeal and lasting quality?

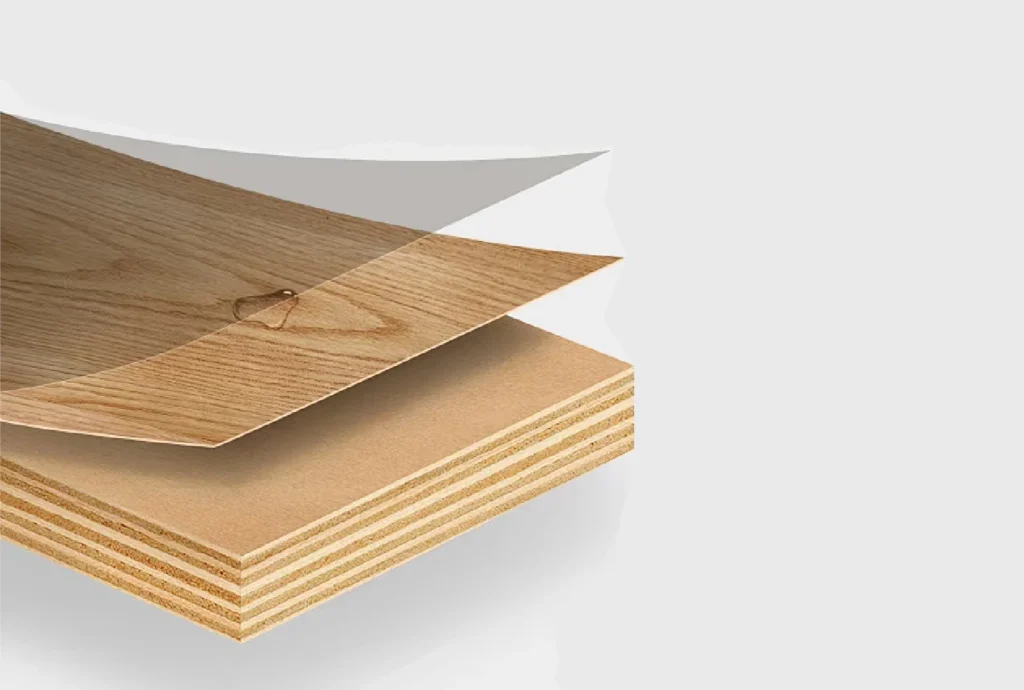

The top materials for premium vanities are solid teak, solid oak, and high-density marine-grade plywood with natural wood veneer. Teak offers the best moisture resistance, while oak balances durability, look, and a more stable supply chain for large orders.

When you aim for a premium, durable bathroom cabinet, these materials stand out:

- Teak: It has a natural oil content that repels water, making it the king of moisture resistance. It is often the most expensive option.

- Oak (White or Red): This is my go-to recommendation. It is very hard, resists scratches, and has a great grain. It accepts finishes well, making it easy to ensure uniformity across a large order.

- Marine-Grade Plywood: This is not solid wood, but it’s a premium engineered option. It uses waterproof glue and is highly stable, resisting expansion and contraction better than some solid woods.

I have seen many trading companies push high-cost woods like teak because the margin is higher. While teak is amazing, for large orders, it presents two big problems: cost and supply variability. The cost difference for hundreds of units is huge. More importantly, sourcing consistent teak for a multi-property deal is hard. Oak, particularly American white oak, offers a much more reliable supply chain. This means consistent color, grain, and fewer production delays, which is critical for hitting a renovation deadline. I advise buyers to see samples of the stain on both oak and teak. The slight difference in luxury appeal is often not worth the big headaches in logistics. The cost-effective longevity of oak truly makes it a smarter choice for bulk.

What Is the Best Wood for a Bathroom Vanity?

Facing hundreds of humidity issues, what is the single best wood to minimize maintenance and guest complaints?

For the best overall wood for a bathroom vanity in bulk, oak is the winner. It offers robust durability, natural antimicrobial properties, and a stable supply chain. Its structural integrity and ability to take a protective finish make it a highly reliable and cost-effective choice for long-term use.

The “best” wood balances four critical factors for hotel procurement:

- Durability and Hardness: It needs to resist nicks and scratches from daily use. Oak is very hard.

- Moisture and Humidity Resistance: It must not warp or grow mold in a humid environment. Oak has a relatively closed grain.

- Cost and Scalability: It must be affordable in large quantities and available consistently without long lead times. Oak’s domestic sourcing is a major advantage.

- Maintenance: It should be easy for hotel staff to clean and maintain without special products. Oak is low maintenance.

A cheaper wood that fails in three years is far more costly than a slightly more expensive wood that lasts ten. Forums like Reddit’s r/woodworking often confirm this, with pros praising oak’s scalability over teak. I’ve personally seen vanities made from soft woods need replacing fast because the drawers started sticking from moisture absorption. Oak’s density and tight grain structure naturally resist this, translating directly into fewer maintenance calls and a better guest experience. This is the difference between a good purchase and a smart investment.

What Is the Best Wood for Absorbing Moisture?

In a high-humidity bathroom, some woods act like sponges and swell, which is a nightmare. Which material is least likely to absorb water?

Teak is the best wood for resisting moisture because its high content of natural oils acts as an inherent water repellent. While teak is superior, oak is the most practical choice because it has a relatively tight grain that, when sealed with a quality finish, provides excellent moisture resistance at a manageable bulk price.

Wood’s ability to handle moisture is about two things: its natural properties and the finish applied:

- Natural Oil Content (Teak): The oils naturally prevent water from penetrating the wood cells.

- Grain Density (Oak): A tighter, denser grain structure is harder for water vapor to enter than an open, porous grain.

- Sealing Finish (Polyurethane): This is the final and most important barrier, creating a protective, waterproof layer.

The real enemy is not direct water splashes but constant high humidity and vapor. No wood is truly “moisture-absorbing” in a good way; we want the opposite—moisture resistance. I always tell my clients to focus on the final finish. You can take a naturally resistant wood like oak and ruin it with a cheap, thin sealant. Conversely, a multi-layer, baked-on polyurethane finish can make even marine-grade plywood a fantastic performer. For bulk orders, insist on knowing the total layers of finish and the drying time between coats. This manufacturing detail is the single biggest predictor of long-term moisture performance, far more than a slight natural advantage one wood might have over another.

How to Make a Wood Vanity Waterproof?

Even the toughest wood will fail without the right treatment. How can you truly waterproof a wood vanity to guarantee its longevity?

To make a wood vanity waterproof, you must use a high-quality, multi-layer polyurethane or epoxy coating on all surfaces, including the edges and the back. This finish is the physical barrier that prevents water vapor from penetrating the wood and causing swelling or mold.

Waterproofing a wooden vanity is a multi-step factory process that a buyer should verify:

- Proper Kiln-Drying: The wood must be dried to a low moisture content (6-8%) before any finish is applied.

- Sealer/Primer Coat: A base layer is applied to soak into the wood pores, enhancing adhesion for the topcoats.

- Multiple Topcoats: Two to three layers of a high-grade polyurethane or conversion varnish are applied.

- Edge Sealing: Every exposed edge and joint must be meticulously sealed to prevent vapor entry.

🛡️ Ensure Hotel-Grade Durability Shop Waterproof Vanities →

When I worked in the factory, I saw how easily corners were cut here. A cheap factory will apply one thin coat and call it a day. A high-quality finish involves sanding between coats and using a catalyzed finish that hardens into a tough, plastic-like shell. For a procurement manager like Emma, I suggest asking for a “cross-cut” sample, which shows the thickness of the finish layers. This is a simple, direct way to check the quality of the waterproofing. A proper waterproof finish is not just about the type of wood; it’s about the manufacturing commitment. A $20 difference per unit often means two more layers of high-grade finish, which is the best insurance against water damage and guest complaints.

How to Ensure Quality When Buying Wooden Bathroom Vanities in Bulk?

When you are ordering hundreds of vanities, consistency is your biggest nightmare. How do you guarantee uniform quality and on-time delivery?

Ensure bulk quality by demanding detailed sample approval for material and finish, requiring a pre-shipment inspection (PSI), and setting clear, measurable AQL standards. Focus on a supplier with proven experience in hospitality projects to guarantee consistency and timely delivery.

Maintaining quality across a large order requires a proactive, systematic approach:

- Golden Sample: Get a single, approved “Golden Sample” signed off for every detail—color, finish, hardware, and construction. Every unit must match this.

- AQL (Acceptable Quality Limit) Standards: Set specific limits for defects (e.g., no more than 1.5% major defects) and include this in the contract.

- Third-Party Inspection: Hire a third party to conduct a Pre-Shipment Inspection (PSI) on a percentage of the final order before it leaves the factory.

Warranty and Service: Get a clear, long-term supply guarantee and a policy for handling in-service failures quickly.

I learned early in my trading career that a strong contract is not enough; you need strong processes. For large projects, I always insist on factory visits or sending my own team for a Mid-Production Inspection. This check catches issues like incorrect internal construction or a weak finish application before the entire batch is finished. It is much easier to fix 100 unfinished units than 500 completed ones. The consistency of color and finish across all units is often a big problem, so specify the required light source and viewing angle for the final QC check. This rigor is the only way to avoid quality inconsistencies that will frustrate a project manager like Emma and affect the guest experience.

Conclusion

Oak offers the best balance for bulk bathroom vanity orders, combining durability, moisture resistance, and supply chain stability. Choose a supplier who focuses on a superior, multi-layer finish to waterproof your investment. If you want to know more about bathroom cabinet craftsmanship, check out the resources at georgebuildshop.

Ready to Upgrade Your Guest Experience?

Don't let bathroom quality compromise your hotel's reputation. Whether you need 50 units or 500, tell us about your project below.

👇 Get Your Custom Solution & Bulk Pricing Now