Are you tired of wood cabinets warping and failing in humid hotel bathrooms? I see this problem all the time. The constant maintenance costs add up.

Stainless steel bathroom cabinets are excellent for bulk hotel orders because they offer unmatched durability against humidity and heavy use, which cuts down on long-term replacement costs. They resist rust, mold, and warping, ensuring a consistent look and low maintenance across many rooms.

I started in a factory and later ran a trading company, so I have seen what works and what does not. The choice of bathroom cabinet material for a big hotel or resort project is critical. You need something that lasts. Let’s look closely at why stainless steel is the right choice for your next large purchase.

Table of Contents

Why Are Stainless Steel Bathroom Cabinets the Ideal Material for Bulk Orders?

Do wood or PVC bathroom cabinets cause you trouble with humidity and heavy guest use? You need a solution that won’t fail.

The ideal material for bulk orders must be durable, easy to clean, and resistant to water damage, which is exactly what stainless steel offers. It withstands the harsh conditions of high-traffic commercial bathrooms, lowering your lifecycle costs and minimizing service disruption.

Stainless steel cabinets are ideal for bulk orders for several key reasons.

- Unmatched Durability: They resist warping, cracking, and swelling, unlike wood or MDF, making them last longer under heavy guest use.

- Superior Moisture Resistance: The material is naturally non-porous and rust-proof (especially grade 304), perfect for steamy hotel bathrooms and humid climates.

- Excellent Hygiene: Stainless steel is easy to clean and does not harbor bacteria or mold, which is important for guest health standards.

- Consistent Quality: When ordering hundreds of units, stainless steel ensures uniform finish and color across the entire project.

I have seen many hotels switch to stainless steel after dealing with warped wood vanities. Procurement professionals in forums often praise its reliability, especially in high-traffic spas. They say, “Finally, no more warped wood after a season!” This shift makes sense because stainless steel’s benefits translate directly into lower operating expenses. It is crucial to vet your supplier to ensure they use a consistent grade, like 304 stainless steel, for every cabinet in your bulk order. This consistency is the key to minimizing in-service failures that can disrupt guest stays.

| Feature | Stainless Steel | PVC/Wood | Benefit for Bulk Order |

|---|---|---|---|

| Water Resistance | Excellent (Rust-Proof) | Poor (Warping/Mold) | Low maintenance, long life |

| Cleaning | Easy, Non-Porous | Requires Care | High hygiene, fast turnaround |

| Life Expectancy | Very High | Medium | Reduces replacement costs |

Is an Aluminum Cabinet Good for a Bathroom?

Are you wondering if aluminum offers the same commercial benefits as steel? You need to know the differences before you buy.

Aluminum bathroom cabinets are also moisture-resistant and lightweight, which makes them easier to install, but they are generally softer and less scratch-resistant than stainless steel, making steel the superior choice for high-traffic hotel use where maximum durability is required.

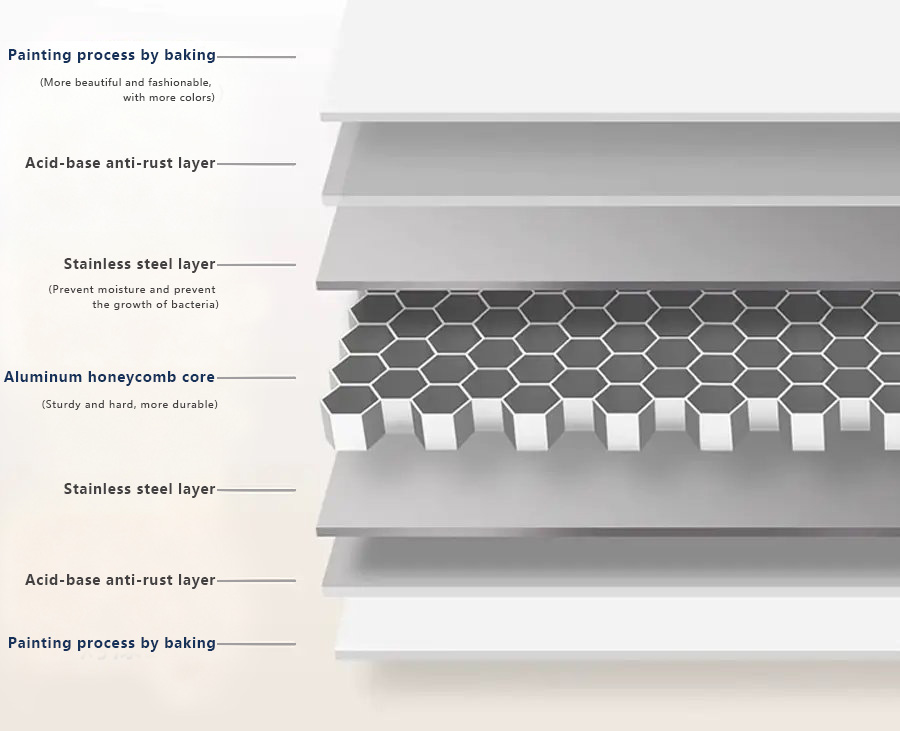

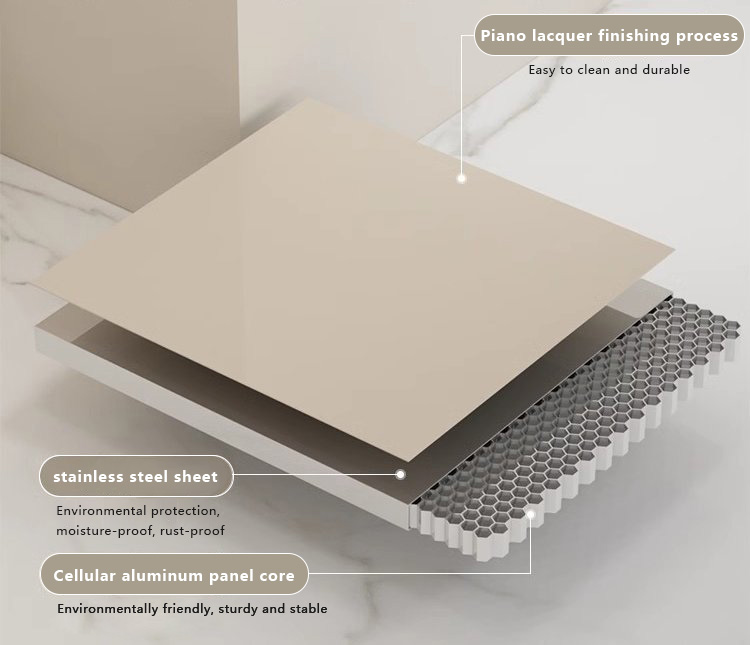

While aluminum is a good option, it does not quite match the industrial strength of stainless steel for every part of a hotel bathroom.

- Weight Advantage: Aluminum is much lighter, which can reduce shipping costs and make on-site installation easier, a major plus for coordinating large renovations.

- Strength Difference: Stainless steel offers higher tensile strength and impact resistance, which is better for a cabinet body that must withstand constant use and cleaning.

- Corrosion Resistance: Both materials resist rust well, but stainless steel’s non-porous surface often makes it slightly easier to maintain in terms of staining and aggressive cleaning chemicals.

- Cost Variance: Aluminum is sometimes slightly cheaper, but the long-term ROI of the tougher stainless steel often balances the cost difference.

When I first started, aluminum was popular because it was easy to handle. However, for a hotel procurement manager like Emma, who prioritizes minimizing in-service failures, I recommend stainless steel for the main cabinet structure. Aluminum can be a great choice for internal shelving or less structural parts where weight savings are more important than maximum surface hardness. Remember that Emma’s main challenge is ensuring consistent finishes across 100+ rooms. Stainless steel’s robust nature makes it easier to keep the finish uniform over years of use and cleaning. Always request a detailed material specification.

Are Stainless Steel Cabinets Expensive?

Does the premium price tag for stainless steel make you hesitate on a large order? You must understand the true cost.

Yes, stainless steel cabinets are typically 20–30% more expensive than standard PVC or MDF options upfront, but their exceptional durability and minimal maintenance result in a lower total lifecycle cost for a hotel, making them a wise long-term investment.

The cost of stainless steel cabinets requires looking beyond the initial purchase price.

- Higher Upfront Cost: The material and the specialized manufacturing process make the initial per-unit cost higher than mass-produced wood or PVC.

- Long-Term Savings (ROI): Hotels save money because they do not have to replace cabinets every few years due to water damage, warping, or mold.

- Maintenance Budget Reduction: The easy-to-clean, rust-proof surface drastically cuts down on the time and money spent on cleaning and repair staff.

- Bulk Discounts: Suppliers often provide significant price breaks for large quantity orders, which can bring the price closer to that of higher-end PVC or solid wood.

When I ran my trading company, I learned that a smart purchase focuses on ROI, not just the sticker price. Forum users often warn that the premium pricing demands a test sample first to match your aesthetic and budget. I always tell my clients to think like this: how much does it cost to take a hotel room out of service to fix a warped vanity? The lost revenue from one night can wipe out any initial savings. Stainless steel prevents this, making the premium price justified for hygiene-focused commercial projects. I advise testing samples and discussing bulk discounts early.

What are the Disadvantages of a Stainless Steel Sink?

Are you worried about the practical drawbacks of using a stainless steel sink? Every material has a weak spot you need to know about. The main disadvantages of a stainless steel sink in a hotel setting are that they are prone to showing visible water spots and fingerprints, which require more frequent wiping, and they can create a metallic sound if water impacts them heavily.

While stainless steel is fantastic, it has a few practical downsides, especially in a high-visibility guest bathroom.

- Fingerprint/Water Spot Visibility: The mirror-like finish, especially on polished surfaces, highlights every touch and splash, requiring staff to clean them more often.

- Noise Factor: A thin-gauge stainless steel sink can sound loud when the water is running heavily or when items drop into it. This is a potential guest experience issue.

- Scratch Potential: Although highly durable, the surface can still be scratched by abrasive cleaning materials or rough objects, and scratches can be noticeable.

- Aesthetic Limitation: Some hotel designs may prefer the seamless look or color options only available with ceramic or solid-surface sinks.

I suggest you address the noise issue by specifying a sink with sound-dampening pads or a thicker gauge of stainless steel. To handle fingerprints, you should consider a brushed or matte finish instead of a high-polish one, which is less reflective and masks smudges better. This small change in finish can significantly reduce the cleaning team’s workload. You must clearly communicate these needs to your manufacturer when you place the bulk order.

What is the Best Grade of Stainless Steel for a Bathroom?

Are you unsure which stainless steel grade provides the best protection against rust and wear? The right grade is key to your long-term investment.

The best and most commonly used grade of stainless steel for a bathroom cabinet is Grade 304, often called 18/8. It provides an excellent balance of corrosion resistance, strength, and weldability, making it ideal for the highly humid environment of a commercial bathroom.

Choosing the right grade is non-negotiable for a large project’s success.

- Grade 304 (The Standard): This grade contains 18% chromium and 8% nickel, which gives it superior resistance to rust from water, steam, and common cleaning agents.

- Grade 316 (The Premium): Known as “marine grade,” this is even more resistant to harsh chlorides (like salt spray), often used in seaside resorts, but it is also more costly.

- Grade 430 (The Budget): This grade has lower nickel content, is magnetic, and is less corrosion-resistant, making it unsuitable for the constantly wet and corrosive environment of a hotel bathroom.

- Consistency is Vital: For a bulk order, you must ensure your supplier promises and delivers 304-grade steel across all 100+ units to avoid quality inconsistencies.

I have seen manufacturers try to cut costs by mixing in lower grades. This is a huge risk for a project where consistency is needed. Forum users often warn of potential inconsistencies across 100+ units if the supplier is not vetted properly. For Emma’s UAE-based hotels, Grade 304 is the sweet spot, offering great performance without the unnecessary expense of Grade 316, unless the property is right on the coast. I would always ask for a material test report before final sign-off on the bulk contract.

🛡️ Procurement Expert Tip

Don't risk your project reputation on uncertain materials. Ensure consistent Grade 304 quality for every unit.

View Hotel-Grade Collection →How to Choose the Right Manufacturer for Wholesale?

Do you feel overwhelmed by the process of selecting a reliable wholesale supplier? Choosing the right partner is the most important step. snippet paragraph:To choose the right wholesale manufacturer, prioritize those who guarantee consistent Grade 304 material, offer clear case studies and long-term supply guarantees, and have a strong track record for timely delivery and quality post-sale service for large projects.

A good manufacturer is a partner who helps you meet your project goals.

- Verify Material Quality: Demand proof (like material test certificates) that they use consistent Grade 304 stainless steel.

- Assess Production Capacity: Ensure they can handle your volume (e.g., 100+ units) and meet your required lead time (be mindful of typical 8–12 week delays for large shipments).

- Check Commercial Experience: Look for a supplier that offers case studies, maintenance guides, and has experience coordinating with hotel renovation schedules.

- Confirm Post-Sale Service: They must guarantee strong after-sales support for any in-service failures or needed spare parts.

When I worked with hotel procurement, vetting the supplier was everything. I advise a deep dive into their quality control process. Specifically, ask about their procedures for checking material thickness and finish consistency across large batches. A reliable manufacturer will offer transparent communication about lead times and will work with you to align their production schedule with your installation windows.

🏨 Project Snapshot: The Coastal Resort Challenge

Conclusion

Stainless steel cabinets are a smart bulk buy for hotels because they last a long time and cost less to keep clean. We at georgebuildshop know this industry well, and we want to share our expertise with you.

Ready to Equip Your 100+ Rooms?

Avoid installation delays and quality disputes. Speak directly with our Hotel Project Specialists today. Fill out the form below to get your Custom Bulk Quote and lead time estimate within 24 hours.