I have watched the global bathroom industry change rapidly over the last ten years. The market for vanities is no longer about simple, standard products. It has shifted from standard models to highly customized solutions. Today, wholesale bathroom vanities are a core strategic asset. In my experience, project differentiation has become the new baseline for success. This is why custom bathroom vanities now dominate the B2B sector. Developers, hoteliers, and large distributors want unique solutions. They need design diversity to meet client-specific needs. They must differentiate their projects in a crowded market.

For B2B buyers like you—large bathroom vanity wholesaler companies and project managers—this shift brings real benefits. Customization leads to higher margins because it creates perceived value. I have seen clients successfully charge a $200 premium on a highly-tailored vanity that only cost $50 more to produce. It strengthens your brand differentiation. It results in better client satisfaction because the product perfectly fits the final space. This article is my guide for you to see past the purchase order. We will look at what truly defines value: from material science and modern bathroom vanity design to supply chain management and strategic partnerships.

Table of Contents

Understanding the B2B Vanity Market Landscape

In my consulting experience, the key buyer segments—large distributors, national contractors, and hotel project managers—share common pain points. They worry about long delivery times. They demand unwavering quality consistency. They need design flexibility for bespoke projects. They struggle with high Minimum Order Quantities (MOQ), which often limits their flexibility in project planning. And, of course, they need predictable pricing.

As a bathroom vanity manufacturer, I believe we must create value by directly solving these pain points. This means shifting production to a modular system. It requires flexible supply chains that can scale up or down easily. It demands a commitment to consistent branding and quality control across every single unit. The industry has moved from generic supply to design-driven B2B partnerships. Bulk orders are still the norm. But now, they require detailed OEM customization and reliable after-sales support and collaboration. Finding the right bathroom vanity wholesaler is not just about price. It is about finding a long-term partner.

For a deeper look into how distributors can stay competitive by leveraging custom bathroom vanities in 2025, see How Custom Bathroom Vanities Help Distributors Stay Competitive in 2025?”.

Material Defines Market Competitiveness

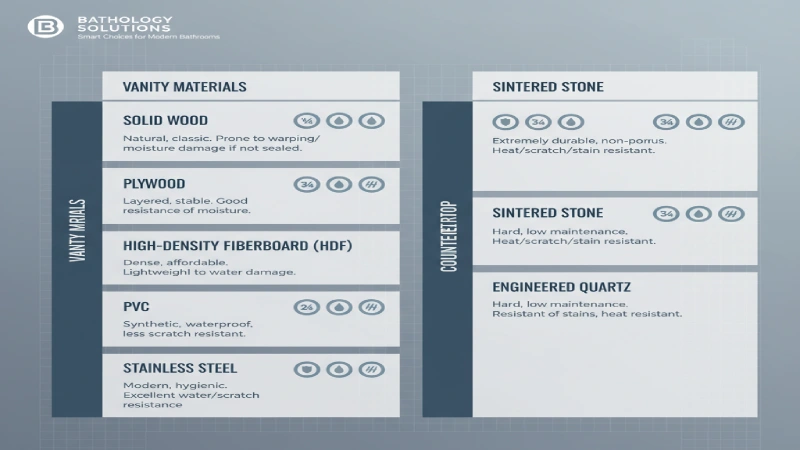

Material selection is the foundation of every durable, long-lasting project. It directly impacts your brand’s credibility and long-term client trust. In my experience, considering the installation environment is key. I call this “environment-based material selection.” For a hotel near the sea, you must select marine-grade plywood. For a heavy-use commercial space, you need durable, high-density fiberboard (HDF). Standard MDF or particleboard simply will not last.

When comparing materials like solid wood, plywood, PVC, or stainless steel, you must balance aesthetics, initial cost, and long-term maintenance. A beautiful rustic bathroom vanity made of solid oak requires more consistent humidity control. A sleek modern bathroom vanity often uses HDF with a durable laminate. The top material is just as vital. A robust sintered stone top will resist scratches and heat better than basic engineered quartz. I have seen projects where opting for cheaper materials ended up costing thousands in repairs and warranty claims just two years down the line.

In my experience, considering the environment where the vanity will be installed is key—I call this “environment-based material selection.” For more details on how material durability and environmental factors define project success, you can read my dedicated article Why Durability and Environment Are the Real Core of Vanity Material Selection.

Integrating Design and Durability for Project Success

I once worked with a developer building luxury resort properties. They wanted unique bathroom vanity ideas. They wanted modern bathroom vanity aesthetics, specifically floating designs. But they were worried about the structural integrity required for large, wall-mounted vanities. This is where engineering meets design. We moved away from simple screw-in brackets. This solution became a standard reference for future projects. We developed an internal stainless-steel frame integrated into the vanity’s core structure. This was hidden, yet it provided exceptional load-bearing strength. It allowed them to achieve the clean, minimalist look they wanted without risking failure.

This project taught us that great design must be structurally sound. We used high-quality, water-resistant plywood for the core. We finished the exterior with a multi-layer, low-VOC paint. Every drawer used soft-close runners rated for commercial use. The small details matter more than anything. We adjusted the standard bathroom vanity dimensions slightly to optimize plumbing access for faster bathroom vanity installation. This simple adjustment saved the client dozens of hours of labor across eighty units. When you are a large bathroom vanity wholesaler, these small efficiencies multiply into major cost savings. This holistic view of the product is critical for B2B success—it is about how it performs for years and how easy it is to install on site, not just how it looks. It is what separates a generic supplier from a strategic partner.

Design Trends That Drive Sales

In my observations, successful B2B selling requires knowing what is selling next year. We see several emerging trends. Minimalist floating vanities remain popular, especially in new residential developments. Modular components allow for easy configuration and repair. Integrated LED mirrors and charging stations are increasingly expected in high-end projects. These are functional innovations. Soft-close drawers are mandatory. Hidden storage and smart space optimization are key for smaller city apartments.

The needs of a hotel project often differ from high-end residential. Hotels need ultra-durable, easy-to-clean finishes. Residential needs more intricate bathroom vanity ideas and design features. From my experience, the business value of design adaptability cannot be overstated. If you can easily adjust bathroom vanity dimensions and finishes on the production line, you can market the product more effectively. It makes your inventory and product line flexible.

For a deeper dive into the latest hotel-focused bathroom vanity trends, see Custom Bathroom Vanity Design Trends for Hotel Projects.

The Customization and Production Process

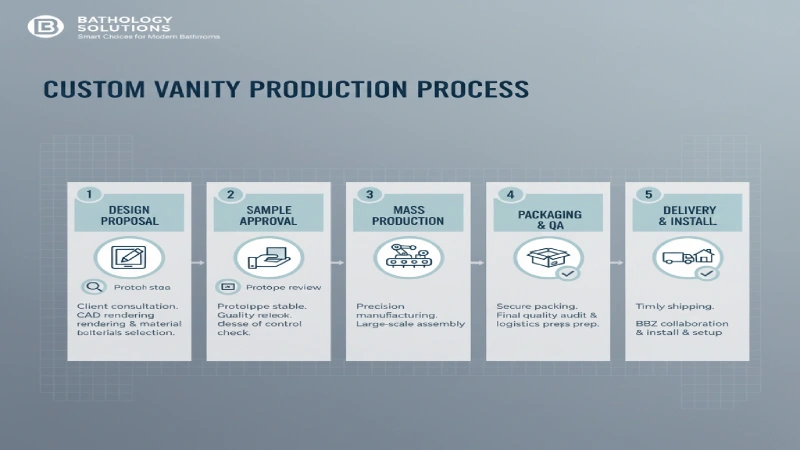

For custom bathroom vanities, the process must be seamless. In my projects, ensuring a seamless process is key to client satisfaction. It usually follows a clear ODM/OEM path. It starts with your design proposal. Then, a sample is produced and approved. Mass production begins, followed by precise packaging and delivery. The key for a bathroom vanity manufacturer is flexibility. We must offer reasonable MOQ flexibility to benefit both small-scale project clients and large national wholesalers.

Production transparency and strict quality control are non-negotiable. I stress this with all my clients. The coordination of logistics is part of the value chain. Post-delivery service is not an afterthought; it is a commitment. It confirms that you, the bathroom vanity wholesaler, can trust the supply chain completely. This approach has helped my clients build trust and long-term partnerships.

Smart customization is a significant trend in bathroom vanity market competition, please see How Smart Customization and Digital Supply Chains Transform B2B Bathroom Vanity Projects.

Scaling Production with Strategic Flexibility

I recall a major challenge with a client focused on the rustic bathroom vanity look. They had a huge order for a chain of themed vacation cabins. They needed a specific, distressed wood finish that was hard to replicate consistently at scale. The initial factory they chose struggled with the volume. The finish on Unit 10 looked completely different from Unit 500. This created a massive quality control issue and a project delay. This taught me the importance of both material strategy and process automation in B2B projects.

When George took over, we did two things differently. First, we focused on the material strategy. We used a more stable engineered core that was less prone to seasonal warping. Second, we implemented a specialized, automated finishing line that applied the distressed texture and protective sealant uniformly. This involved heavy investment in our machinery. The result was perfect consistency across thousands of units. We even adjusted the standard bathroom vanity dimensions slightly to account for the unique cabin layouts. This ability to deliver a highly specific, custom bathroom vanities product without sacrificing consistency is the hallmark of a true B2B partner. It ensures your projects stay on schedule. It is what allows you, the distributor, to maintain a competitive edge and high client confidence. That factory’s commitment to quality over speed saved the project and secured the long-term relationship.

Case Snapshot: Resort Chain Project

Sustainability: The Next Growth Driver

In my experience, the global demand for eco-friendly bathroom furniture is no longer a niche. It is a major growth driver. Materials that meet sustainability standards—like FSC-certified wood, recycled stone countertops, and low-VOC finishes—are becoming market differentiators. For large distributors, this offers a clear marketing advantage. Offering eco-friendly custom bathroom vanities further differentiates your portfolio. It helps you comply with the rising number of green building projects. This requires careful balancing of eco-materials with production feasibility and cost efficiency, but the market value is undeniable. For B2B wholesalers, offering sustainable options strengthens your brand and expands your market reach.

To dive deeper into the sustainability trend of custom bathroom vanity, see Why Wholesalers Must Champion Environmental Stewardship: The Core B2B Advantage in Custom Vanity Supply.

Choosing the Right Manufacturing Partner

From my experience, your choice of supplier defines your market success. You must look at four main criteria. First, material sourcing and control. Second, advanced design and custom bathroom vanities capability. Third, proven OEM/ODM experience and flexibility with bathroom vanity dimensions. Finally, delivery reliability and strong after-sales support for any potential bathroom vanity installation issues. The right partnership dramatically increases your efficiency and market reach and has a direct impact on your ability to deliver high-quality projects on time. As a bathroom vanity manufacturer, I focus on building partnerships that combine design, material expertise, and reliable delivery. At George, we provide integrated design, material, and production support because we understand your needs. We are here to simplify your entire supply chain.

Conclusion

The key success equation for the modern B2B market is clear. It is not about the lowest price.

Material + Design + Sustainability + Supply Chain = Market Competitiveness.

The price tag on a modern bathroom vanity is just the starting point. I urge you to rethink your vanity sourcing strategy, and I encourage you to rethink your vanity sourcing strategy based on long-term value. Choose partners who see your business goals as their own. Focus on products that deliver years of trouble-free performance, because that is where real profit and client loyalty are achieved.

Partner with a bathroom vanity manufacturer who understands your market needs.

George provides design, material, and production support for B2B vanity projects worldwide.

Ready to Upgrade Your Property?

Join hundreds of hotels and resorts that trust George for quality and precision.

Fill out the form below to get a factory-direct quote or consult with our project specialists today.