Commercial specifications for a whirlpool bathtub hotel system are defined by five critical engineering requirements:

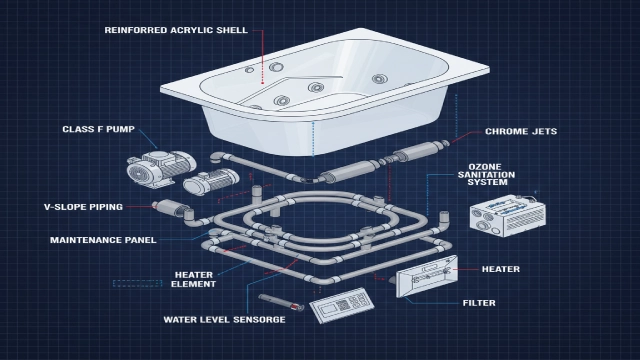

Structural Load: min. 500kg static capacity

Hydraulic Hygiene: V-slope piping with <5ml residual water

Electromechanical Durability: Class F insulation pumps with $\ge 15,000$-hour duty cycles

Automated Sanitation: Ozone or UV-C sterilization

Maintenance Accessibility: min. 400mm service panels

These parameters apply exclusively to hospitality environments; failure to define these at the design stage—rather than component quality—is the primary cause of operational failure.

Commercial whirlpool bathtubs are engineered systems, not decorative fixtures.

Table of Contents

Why Commercial Whirlpool Bathtub Specifications Matter in Hotel Projects?

In my ten years at George Group, I’ve observed that while aesthetics sell rooms, engineering keeps them open. In hospitality projects, specifications define your operational risk. Once a whirlpool bathtub hotel unit is installed and tiled in, 80% of specification mistakes become irreversible without full-scale demolition.

At this early stage, responsibility sits with the project team—not operations or housekeeping. Hotels with whirlpool bathtubs often fail to meet guest expectations because the operating environment is drastically different from residential use. While a home unit might be used twice a week, a hotel unit faces heavy-duty cycles daily.

Hotels with whirlpool bathtubs that ignore these technical realities face a destructive domino effect:

Room Out-of-Service (OOO): Result: Immediate revenue loss. Cause: Inaccessible pumps or improper drainage specs.

Maintenance Bloat: Result: Inflated labor costs. Cause: Residential-grade components specified for a high-occupancy commercial environment.

Reputational Damage: Result: Negative hygiene reviews. Cause: Non-self-draining pipe designs that harbor bacteria.

Source: Global Growth Insights – Whirlpool Bath Market Report

What Are the Most Common Specification Mistakes in Hospitality Whirlpool Bathtub Projects?

Across dozens of international hotel projects, these three mistakes appear consistently. In our experience, residential-grade pumps rarely survive beyond the first year in high-occupancy environments.

1. Selecting Products Based on Showroom Samples

This happens when suppliers are chosen for aesthetics rather than duty-cycle documentation. This is not a product failure; it is a specification failure. This is typically the stage where George Group is involved—assuring technical compliance before procurement begins.

2. Ignoring Structural Load and Floor Reinforcement

A whirlpool bathtub hotel unit can exceed 500kg–600kg when filled. In one Dubai project, ignoring live-load specs led to a $200,000 retrofitting bill after the floors settled. This is not a product failure; it is a specification failure.

3. Inadequate Drainage and Biofilm Build-up

In hotels with whirlpool bathtubs (Jacuzzi-style systems), hygiene complaints usually trace back to stagnant water in internal lines. In hospitality engineering, water that cannot drain is considered contaminated. This is not a product failure; it is a specification failure.

Across all three cases, the pattern is consistent: operational failures in hotel whirlpool systems are rarely caused by manufacturing defects, but by specification decisions made long before procurement.

Source: Whirlpool Bathtub Market, Global Outlook and Forecast 2025-2032

What Key Specifications Should Be Defined for Commercial Whirlpool Bathtubs in Hotels?

The Minimum Baseline for Risk Control (Not Optional Upgrades)

These values should be treated as non-negotiable baselines, not optional upgrades, during design and tender evaluation. In projects with incorrect specifications, failures usually appear within 6–12 months.

Key Commercial Bathtub Specifications

Structural Load

Pump Life

Drainage

Material

Safety

Source: Accio Premium Whirlpool Bathtub

How Do Engineering Specifications Affect Whirlpool Bathtub Performance in Hotel Projects?

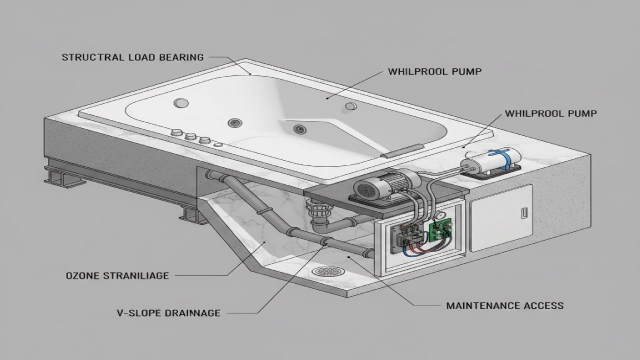

Structural Load Capacity and Base Support

From a project risk perspective, the bathtub frame matters as much as the tub itself. We recommend a #304 stainless steel support frame. If your supplier cannot provide load distribution drawings, this is a major red flag.

Drainage Design and Anti-Stagnation

Most whirlpool bathtub installation failures start with missing drainage specs. This is critical for hotels with whirlpool bathtubs, where hygiene expectations are non-negotiable. High-end systems must utilize a V-slope design. If the system relies on manual flushing only, the operational risk remains unacceptably high.

Pump System Durability and Duty Cycle

A whirlpool bathtub installation requires a motor with Class F insulation. Residential pumps are not built for the heat generated by constant commercial use. If this sounds familiar, you’re not alone—this is where most hotel projects underestimate the risk.

How Should Whirlpool Bathtubs Be Specified at the Design Stage? (A 3-Step Method)

This three-step method is how we help international hotel developers eliminate most failures before construction begins.

Step 1: Design Coordination

The architect and MEP team must mandate a maintenance access panel (min. 400mm x 400mm).

Step 2: Performance Definition

Define the technical baseline (pumps, sanitation, load) in the technical specifications document before seeking quotes.

Step 3: BOQ Language (Preventing “Down-Spec”)

Use precise language to prevent contractors from selecting cheaper alternatives. In our experience, this single BOQ sentence prevents more failures than any after-sales warranty:

BOQ Example (Recommended for Copy-Paste):

“Commercial-grade whirlpool bathtub with self-draining V-pipe system, $\ge 15,000$-hour rated pump, 400x400mm accessible service panel, and integrated ozone sanitation system.”

How Do Maintenance Requirements and Operational Factors Affect Long-Term Performance?

How to maintain a whirlpool bathtub in hotels is determined at the specification stage. If maintenance feels complicated, the specification was likely incomplete. We advise hotels with whirlpool bathtubs to run a monthly deep-clean, but the efficiency of this task is decided during the whirlpool bathtub installation phase.

FAQ: Are Whirlpool Bathtubs Suitable for All Hotel Projects?

No. While they significantly boost ADR in luxury suites, they require a committed O&M infrastructure. If a project does not have the structural capacity, access planning, or O&M commitment, a whirlpool system should not be specified.

Conclusion: Specifications Define Performance

The success of a whirlpool bathtub hotel feature is decided long before the first guest checks in. This is exactly why many developers involve George Group during the specification phase—before procurement, not after failure.

George Group specializes in bridging the gap between high-end design and rigorous commercial engineering. Our goal is to ensure your project’s luxury is built on a foundation of reliability.

Are you currently in the design or tender stage? The following checks are critical to your project’s success:

Review your current BOQ for commercial-grade compliance.

Validate pump duty-cycle assumptions based on your projected occupancy.

Check access panel and drainage dimensions against architectural plans.

Most failures we are asked to fix could have been eliminated with a 30-minute specification review at the design stage.

Contact me to ensure your hospitality project meets these global standards today.

This specification-focused article connects to a larger system-level guide that explains how cost, engineering decisions, and coordination risks impact commercial whirlpool bathtub performance in hotel projects.

👉 Commercial Whirlpool Bathtubs for Hotels & Resorts: Cost, Specification Risks, and How to Avoid Project Failures

One-Stop Bathtub & Faucet Solutions for Commercial Projects

We support hotel and commercial projects with integrated bathtub and faucet solutions that reduce specification gaps and coordination risks.

▼ Contact us via the form below to evaluate your project and collaborate. ▼