Core Insight

Whirlpool bathtubs fail in hotel projects not because they are poorly manufactured, but because they are specified, installed, and maintained as standalone products instead of integrated operational systems.

In commercial hotels, a whirlpool bathtub is a high-intensity mechanical system. When usage frequency, drainage design, maintenance access, and lifecycle serviceability are ignored at the specification stage, failure is not a possibility—it is a predictable outcome. This is not a product failure; it is a system definition failure.

As a hotel project manager, developer, or asset owner, you aren’t just buying fixtures; you are investing in a guest experience that must remain flawless for the next decade. After ten years in the sanitary ware industry—overseeing thousands of installations from luxury resorts to urban business hotels—I have seen a recurring, painful pattern. What surprised me most was not how often failures happened, but how predictable they were once you understood the system behind them. Across commercial whirlpool bathtub installations in global projects, these patterns are consistent—and entirely preventable.

If you’re evaluating recurring failure patterns in hotel whirlpool bathtub projects, this article complements a full lifecycle guide that addresses cost, specifications, and risk prevention at a project level.

👉 Commercial Whirlpool Bathtubs for Hotels & Resorts: Cost, Specification Risks, and How to Avoid Project Failures

Table of Contents

Why do Whirlpool Bathtubs Fail in Hotel Projects?

In my experience, whirlpool bathtubs fail in hotels for one primary reason: they are specified as products, not operational systems. It is rarely a result of poor manufacturing quality. Instead, it is the delayed consequence of treating a complex mechanical installation as a standalone piece of furniture. This is a reality I have seen repeated across dozens of hotel projects over the past decade. If you’ve managed more than one property, you’ve likely had that moment where you think, “Didn’t we solve this problem in the last project?”

Why Whirlpool Bathtub Failures Keep Repeating Across Hotel Projects?

When the same failures appear across different hotels, brands, and regions, the problem is not the bathtub itself—it is how the system was defined at the project stage. I often hear teams say, “This only happened on one project,” or attribute it to bad luck or a specific supplier issue. In reality, I see the same failure patterns repeated regardless of the budget. This is why these failures appear again and again—across brands, regions, and price tiers.

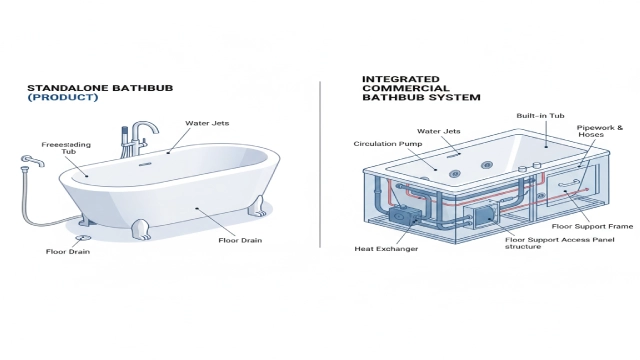

In my consulting work, I’ve noticed that when teams focus only on the upfront cost of whirlpool bathtub units, they unknowingly lock in higher lifetime costs. Designers focus on the aesthetic, and procurement focuses on the unit price. But in a commercial setting, a bathtub is a high-intensity machine. Treating a bathtub as a simple product instead of a commercial bathtub system is a structural risk that sets the project up for failure before the first guest even checks in.

Source: Global Growth Insights

What Is the Real Problem with Treating Whirlpool Bathtubs as Products Instead of Systems?

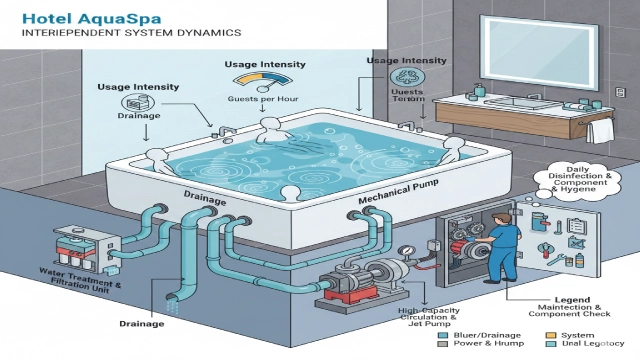

To solve the reliability issue, we must redefine what we are buying. In a commercial context, a whirlpool bathtub system consists of four interdependent elements. At George Group, this is how we define a commercial bathtub system—an integration often overlooked during early design coordination:

- Usage Intensity: A residential tub might be used twice a week. A hotel bathtub in a high-occupancy property might be used twice a day, 365 days a year. This intensity leads to motor failure if the unit is specified using residential logic.

- Mechanical Synergy: The interaction between the pump, pipework, and local power supply. Understanding how to install a whirlpool bathtub correctly is an engineering task; improper synergy is a leading cause of installation-related leaks.

- The Invisible Infrastructure: This includes floor load-bearing capacity and waterproof sealing. Failure here results in catastrophic water damage to the floors below.

- Life-cycle Accessibility: You cannot realistically clean whirlpool bathtub internal lines or service a motor if the system was never designed for access. This directly results in high maintenance overhead and room downtime.

What Five Predictable Failure Patterns Are Caused by This Mistake?

These are not edge cases. They are the most common outcomes when systems are poorly defined. Once you understand these gaps, the failures below stop looking random and start looking inevitable.

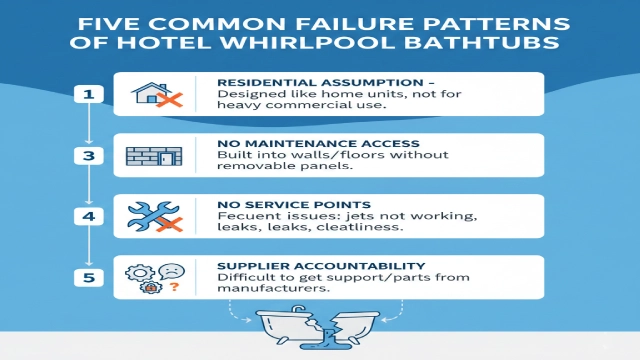

Failure 1: Residential Assumptions in Commercial Environments

The most common mistake is specifying a residential-grade unit for a five-star resort. Residential motors aren’t designed for back-to-back run times. This mismatch between residential assumptions and commercial bathtub requirements is a leading cause of premature motor burnout.

Failure 2: Maintenance Was Never Designed Into the System

I once visited a project where the designer tiled a tub into a granite platform with no access panel. When a component failed, the hotel spent $2,000 just to break the stone. No cleaning protocol can compensate for this. Trying to clean a whirlpool bathtub regularly will not help if physical access is blocked, turning a minor fix into a major expense.

Failure 3: No Access, No Service, No Recovery

Planning how to install a whirlpool bathtub should always include accessible service points clearly marked on drawings. Without a concealed, aesthetic access hatch, your luxury amenity is a “disposable” item. This makes the system impossible to recover when a simple sensor or pipe fails, forcing a full room renovation.

Failure 4: Guest Complaints Are System Feedback

In a hotel, noise or odor complaints are not subjective feedback—they are operational diagnostics. Odors are usually caused by stagnant water in pipes that aren’t properly sloped. No amount of surface cleaning can fix the underlying system design of the hotel bathtub.

Failure 5: Suppliers Delivered Products, Not Accountability

Supplier responsibility often ends at delivery. To avoid this, you need a project-focused whirlpool bathtub manufacturer who stays accountable through the installation phase. When you buy a product, you own the risk; when you buy a system, you share the accountability.

Why These Failures Are So Expensive After Opening?

Once a hotel is operational, even minor specification mistakes can multiply into significant financial losses. In hotel projects, the true cost of a whirlpool bathtub is not the unit price—it is the cost of failure after opening.

Consider how minor specification errors escalate into major liabilities once the property is operational:

Hidden Costs of Bathtub Failures

Pump / Motor Failure

Improper Drainage

Leak to Floor Below

No Access Panel

What Actually Happens After a Whirlpool Bathtub Fails in a Hotel Project?

At this point, many project managers think, “We will just fix it if it breaks.” But after a failure occurs, the situation quickly evolves from a “maintenance ticket” into a project accident:

Room Downtime Is the First Cost: You aren’t just losing one tub; you are losing a premium room’s nightly revenue. In many cases, a leak causes a “vertical shutdown,” forcing the rooms directly below to be taken out of service as well.

Waterproofing Damage Is Often Irreversible: To fix a motor or a deep-seated leak in a poorly designed system, you often have to break tiles and marble. Once the original waterproofing membrane is punctured for a mid-operation repair, it is nearly impossible to restore the seal to its original factory-standard integrity.

Responsibility Quickly Becomes Unclear: The supplier blames the plumber; the plumber blames the site condition; the designer blames the procurement team. While the finger-pointing continues, the owner absorbs the 100% of the operational loss.

Operational Impact Extends Beyond the Bathroom: A single “musty smell” or “noisy pump” review on TripAdvisor can devalue your ADR (Average Daily Rate) and damage the brand’s luxury standing far more than the initial cost of whirlpool bathtub savings.

Why Most Hotel Projects Realize These Risks Too Late

You might wonder why these risks aren’t highlighted more often during construction. It is because of three structural flaws in the industry:

Decisions Are Fragmented: The person who picks the tub (Design) is rarely the one who installs it (Contractor), and neither is the one who has to live with it (Operations). There is no “System Owner” during the procurement phase.

Whirlpool Is Treated as a Product Line Item: It is categorized alongside vanities or mirrors. But a mirror doesn’t have a motor, pressurized plumbing, or drainage slopes.

Problems Appear After Handover: All these risks are “silent” during the first few months. They explode during peak occupancy or after the warranty period, at which point the low-cost initial fix is no longer an option.

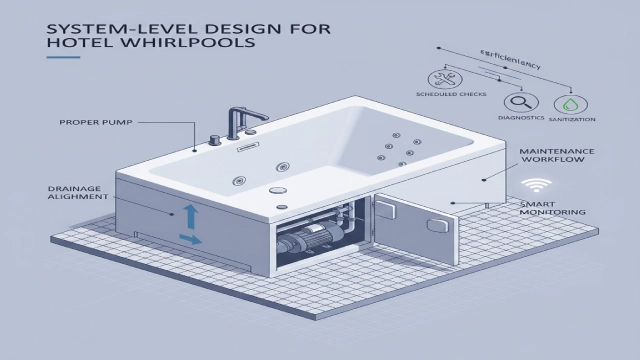

How to Avoid These Failures: A System-Level Mindset?

Avoiding these disasters starts with a mindset shift at the specification stage:

Design for Commercial Rigor: Ensure every commercial bathtub is rated for the specific occupancy and usage frequency of your property.

Integrate Maintenance and Access: Ensure the access panel is a mandatory specification item in your architectural drawings.

Coordinate Services Before Installation: Align drainage, electrical, and structural requirements months before delivery.

Work with Project-Focused Partners: At George Group, we act as an extension of your engineering team, providing technical integration that high-stakes hotel projects require.

Conclusion: Most Failures Are Predictable

Most whirlpool bathtub failures in hotels originate at the specification stage—not on opening day. They are the delayed consequences of treating an operational system as a simple product. When you prioritize system-level design over the lowest initial cost of whirlpool bathtub, you protect your property from negative reviews and skyrocketing maintenance costs.

A short system-level review at this stage often prevents years of operational headaches. At George Group, we don’t just supply products; we partner with you to engineer long-term operational success.

Ready to secure your project’s ROI?

Contact us and the George Group Team today for a professional system-level assessment of your technical specifications. Let’s identify and eliminate hidden risks in your bathroom layouts before they become costly liabilities.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼