Hi there! I’m Helen, and I’ve spent the last ten years navigating the intricate world of sanitary ware. Over the past decade, I’ve walked through hundreds of hotel construction sites and procurement offices, helping project managers like you balance the scales between aesthetic luxury and operational longevity.

If you are a hotel project manager or a procurement lead, you know the “bathtub dilemma” all too well. A pristine, gleaming bathtub is the centerpiece of a luxury guest experience. However, after just a year or two of high-occupancy turnover, many of those same tubs start to look dull, yellowed, or perpetually “dirty” despite constant scrubbing.

The Hidden Industry Conflict

Almost every hotel team I work with eventually asks the same question: what to use to clean bathtub surfaces without damaging them? Choosing the wrong approach to cleaning bathtub surfaces is one of the most expensive hidden mistakes in hotel operations.

The problem is, most commercial bathtub cleaner products on the market are designed for short-term visual cleanliness—stripping away grime in seconds—but they are not designed to protect long-term surface integrity. In many hotels, aggressive cleaning chemicals are not solving bathtub problems—they are creating them. What looks like a cleaning solution is often the hidden cause of surface damage, recurring stains, and rising maintenance costs.

Table of Contents

What Is the Hidden Cost of “Cleanliness” in Hotel Whirlpool Bathtub Projects?

We live in an era where hygiene is non-negotiable. According to reports from Verified Market Reports, the global hospitality cleaning services market is seeing unprecedented growth as hotels double down on sanitation. But in the rush to sanitize, many housekeeping teams rely on a bathtub cleaning chemical that provides immediate results while triggering long-term structural degradation mechanisms.

At George Group, we don’t just see ourselves as a manufacturer; we are partners in lifecycle cost planning. When a bathtub loses its “factory glow” within 18 months, it’s a financial failure. Replacing 200 bathtubs in a mid-rise hotel can cost hundreds of thousands of dollars in materials and labor. Often, the manager asks me for the best bathtub cleaner to fix the yellowing, only for me to have to explain that the damage is already permanent.

How Cleaning Chemicals Cause Invisible but Permanent Bathtub Damage?

A. Surface Erosion and Gloss Loss

Most high-end hotel tubs are made of acrylic or enameled porcelain. High-reactivity chemical agents—including harsh acids, strong alkalis, and undiluted bleach—act as corrosives. They eat away at the top gel coat or glaze, leading to “micro-pitting.” Industry research on chemical–surface interactions confirms that these agents create micro-damages that essentially “sand down” your bathtub’s finish every single day.

B. Recurring Stains and the “Pore” Effect

When a bathtub mold cleaner or heavy-duty descaler is too abrasive, it strips the protective seal off the material, leaving the surface porous. Instead of soap scum and body oils sliding off the surface, they get trapped inside these micro-pores. This creates a “Chemical Injury → Rapid Re-staining” loop. Your team spends more time cleaning bathtub surfaces than ever before, increasing labor costs and reducing your room turnover efficiency.

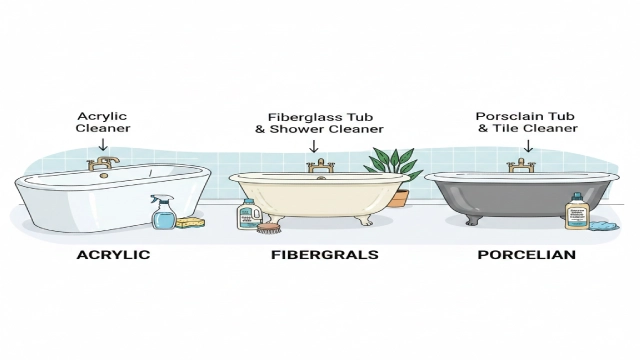

C. Which Bathtub Cleaner Works for Each Material?

From an engineering perspective, using the wrong cleaning chemical is equivalent to sanding the bathtub surface at a microscopic level. You must match the chemistry to the substrate.

Recommended Bathtub Cleaning Logic by Material

Acrylic Bathtub

Fiberglass Bathtub

Porcelain Bathtub

How Should Expertise Be Applied to Define the “Best Bathtub Cleaner”?

In my experience, there is no single best bathtub cleaner—only the best one for the right material and usage frequency. When I consult for major developers, I use three criteria to evaluate a bathtub cleaning chemical:

pH Range: For daily hotel use, a pH between 6 and 8 is ideal. Anything lower (acidic) eats the shine; anything higher (alkaline) makes the material brittle.

Residue Behavior: Does the cleaner leave a film? Residual chemicals “bake” into the surface under hot water, causing yellowing.

Compatibility with Sealing Layers: A professional bathtub cleaner must coexist with the factory-applied polymer seals used by George Group.

A Real-World Project Insight

In a 180-room coastal hotel project in Southeast Asia, the operator was facing a 15% annual bathtub replacement rate due to severe “yellowing” and cracking. By switching from a bleach-based commercial bathtub cleaner to a material-specific, pH-neutral protocol integrated with our material engineering advice, they reduced replacement rates by 40% within two years. Figures are based on internal maintenance records reviewed during a two-year post-handover audit.

What Causes Damage to Whirlpool Bathtubs, and Why Does It Happen?

Beyond the chemicals themselves, the damage is often a result of:

Extended Dwell Time: Leaving a bathtub mold cleaner on the surface for 20 minutes instead of the recommended 5.

Mechanical Friction: Using abrasive pads that create permanent scratches.

Natural Bathtub Cleaner Myths: “Natural” does not automatically mean “material-safe” in commercial hospitality applications. Vinegar, for instance, is too acidic for certain stone resins. Understanding what to use to clean bathtub units requires professional guidance, not just “green” labels.

What Solutions Does the George Group Lifecycle Approach Offer for Whirlpool Bathtub Management?

From an engineering perspective, cleaning chemicals should be treated as part of the bathtub system—not as an afterthought. We suggest a transition from “reactive scrubbing” to system-based maintenance.

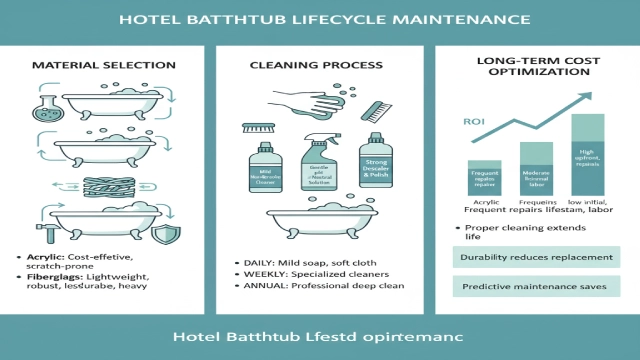

A. Material Selection and Engineering

At George Group, we design our tubs with cleaning compatibility guidance in mind. Our high-density acrylic and stone resin composites are engineered to have lower porosity, making them naturally resistant to stains without needing a harsh bathtub cleaner.

B. Proper Cleaning Agent Usage

Avoid the “Big Three”: No hydrochloric acid, no concentrated bleach, no ammonia.

The Eco-Professional Shift: Use a natural bathtub cleaner specifically formulated for commercial hospitality—balancing environmental safety with professional strength.

C. Cleaning Method Optimization

Soft Tools Only: Microfiber cloths only.

Localized Treatment: Use bathtub mold cleaner only on grout, never as a total-surface soak.

The Final Rinse: A critical SOP. Freshwater must remove all chemical traces after every guest checkout to prevent accelerating surface degradation mechanisms.

FAQ

- What is the safest commercial bathtub cleaner for hotels?

The safest choice is a pH-neutral, non-abrasive liquid detergent. Avoid any products containing abrasive particles or high concentrations of bleach, as these destroy the surface glaze over time.

- Are natural bathtub cleaners always better for acrylic tubs?

Not necessarily. While they are safer for the environment, “natural” acids like citric acid or vinegar can still etch certain stone resin finishes if left for too long. Always check the material compatibility first.

- How often should hotels change their bathtub cleaning chemicals?

You should review your bathtub cleaning chemical selection annually or whenever you change material suppliers. As material science evolves, so should your cleaning protocols.

Conclusion

From an engineering standpoint, bathtub maintenance failures are rarely caused by poor cleaning effort—they are caused by poor chemical decisions. After a decade in this industry, I’ve learned that a hotel’s reputation is built in the bathroom. A guest will never forget a stained bathtub.

Aggressive cleaning chemicals are often creating the very problems you are trying to solve. By optimizing your choice of commercial bathtub cleaner and focusing on material science, you protect your brand and your bottom line.

At George Group, we provide more than just hardware; we provide a Lifecycle Cost Planning system. We help you select the right materials and provide the technical protocols to keep them pristine for 10+ years.

If you are reviewing bathtub specifications or maintenance protocols for an upcoming project, these resources may help:

Hotel Bathtub Chemical Compatibility Matrix (A technical list of which chemicals to ban).

Material–Cleaner Matching Guide (Match your specific tub to the right protocol).

Pre-Project Durability Review (A consultation for your next project).

Would you like me to send you our “Hotel Bathtub Chemical Compatibility Matrix” or provide a free Pre-Project Durability Review for your next development? Let’s ensure your bathtubs stay as brilliant as the day they were installed.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼