Premium Ceramic Toilet Manufacturer in Foshan

One-Piece Toilet Series

Our one-piece ceramic toilets are manufactured using premium vitreous china for a seamless, easy-to-clean finish. Featuring advanced siphonic jet flush technology and S-trap configurations, built for high-performance wholesale and luxury engineering projects.

Wall-Hung Toilet Series

As a leading sanitary ware manufacturer, our wall-hung series features high-density vitreous china and advanced rimless flush technology. Designed for durability in commercial and residential projects.

Intelligent & Smart Toilet Series

Leading the industry as a professional smart toilet manufacturer. Our intelligent series features automatic open-close, foot-sensor flushing, and heated seats. Engineered with UV sterilization for luxury electronic water closet projects worldwide.

Trusted By Global Leaders

We are proud to be the long-term manufacturing partner for top developers, contractors, and premium hospitality brands worldwide.

Tell Us Your Project Requirements

We respect your privacy. Your number is used strictly to discuss your project and share your quote or proposal via WhatsApp. No spam, no cold calls.

⚡ For faster service: simply click the WhatsApp button below to chat with us directly.

Who We Serve

We provide professional sanitary ware solutions tailored for the specific requirements of the global construction and trade industry.

Real Estate & Construction

Reliable supply for large-scale developments. Certified water-saving toilets meeting CUPC/CE building codes.

- Residential Developments

- Commercial Skyscrapers

- Public Infrastructure Projects

Wholesale & Distribution

Empowering local distributors with factory-direct pricing and stable inventory of sanitary ware.

- Regional Wholesalers

- Sanitary Ware Showrooms

- Online Retail Networks

Hospitality & Projects

Luxury smart toilets and durable ceramic closets designed for high-frequency usage in hotels.

- Luxury Hotel Chains

- High-end Resorts

- Serviced Apartments

OEM/ODM Brand Partners

Complete private label solutions from initial design to final production for global brands.

- Private Label Branding

- Custom Product Design

- Confidential Manufacturing

Looking for a reliable manufacturing partner for your next project?

Contact Helen for Project QuoteFactory Direct Supply

Precision Manufacturing

Meet Global Standards

We operate a state-of-the-art sanitary ware production base in Foshan. Using High-Pressure Casting and 1280°C Tunnel Kiln technology, we ensure every toilet body achieves fully vitrified porcelain density (Water absorption < 0.2%). Our 100% appearance check and leakage test guarantee zero defects for your project.

Manufacturing

Excellence

We don't just assemble; we manufacture. From raw clay mixing to 1280°C kiln firing, control every step of the ceramic toilet production process in our Foshan facility.

1280°C Tunnel Kiln Firing

Our toilets are fired for 22 hours in 128-meter tunnel kilns. This high-temperature vitrification ensures the vitreous china body has a water absorption rate < 0.2%, preventing odor and cracking.

Massive production capacity to support large-scale real estate projects and wholesale distribution.

Check Lead Time100% Leakage Test

Every single toilet undergoes a vacuum leakage test and a flush performance test before packaging. No random sampling.

View QC VideoGlobal Logistics & OEM

Zero-Breakage Packaging: 5-ply honeycomb cartons for safe ocean freight.

OEM Service: Custom mold design, logo printing, and packaging for your private label.

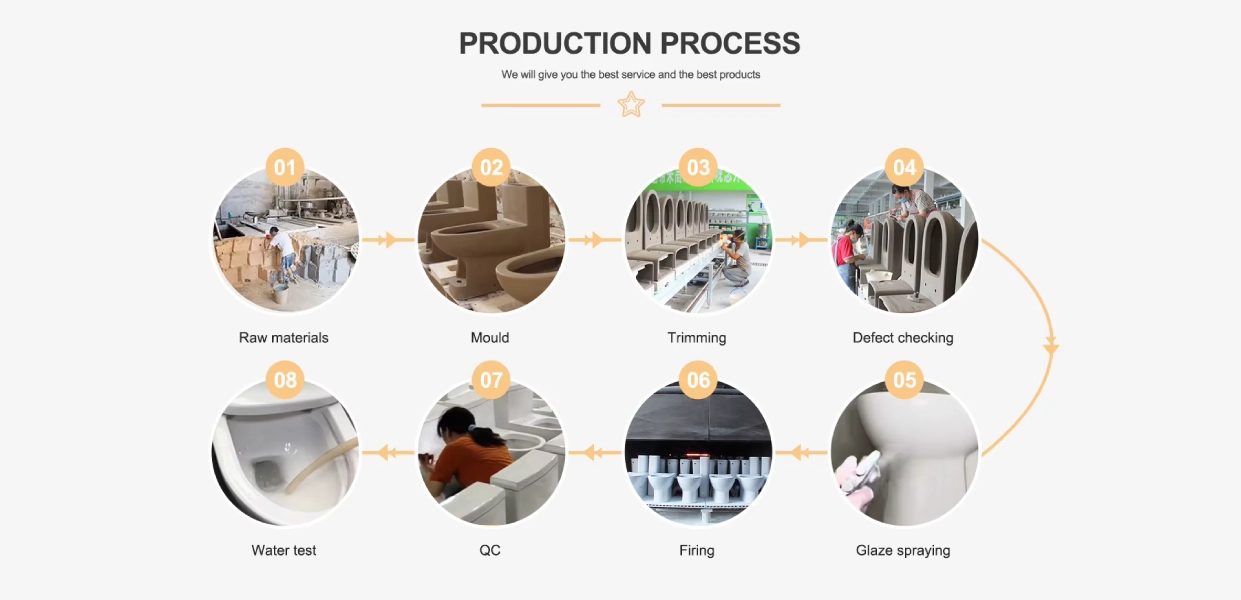

8-Step Quality Manufacturing

Transparency is our standard. Explore the complete lifecycle of a George toilet, from raw clay to the final flush test.

Raw Materials

Selection of premium quartz, feldspar, and clay. Mixed into high-density slurry to ensure a strong ceramic base.

Moulding (Casting)

High-pressure casting in resin molds creates a uniform body with defined curves and internal trapways.

Trimming

Skilled artisans manually smooth the mold lines and sponge the surface to prepare for inspection.

Defect Checking

Green Body Inspection: We check for pinholes or cracks before firing. Defective bodies are recycled immediately.

Glaze Spraying

360° robotic spraying applies a 1.2mm coat of antibacterial Nano-Glaze, covering every inch including the pipe.

Kiln Firing

Fired at 1280°C for 22 hours. This turns the clay into fully vitrified porcelain with <0.2% water absorption.

QC Inspection

Finished Product QC: Examining surface flatness, glossiness, and checking for any deformation after firing.

Water Test

100% Flush Test: Every toilet is connected to water to verify siphonic power, seal integrity, and no leakage.

Project Workflow

A standardized 5-step engineering process to ensure your bulk ceramic toilet order meets international plumbing codes.

Specs Review

Confirm rough-in (300/400mm) and flush type. We issue a formal quote.

CAD Sign-off

Engineer provides technical drawings. You approve dimensions before molding.

Kiln Production

20-day cycle: High-pressure casting and 1280°C firing for durability.

QC & Testing

Vacuum leakage test & flush test. We send inspection videos for approval.

Global Delivery

Secure packing and shipping to your port or jobsite (DDP available).

Expert Sourcing FAQ

Common questions from B2B buyers regarding MOQ, shipping, and quality assurance.

For standard stock models, our MOQ is 50 sets. For custom OEM branding or specific project designs, the MOQ starts at 100 sets. We highly recommend mixed container loading (1x20GP or 1x40HQ) to optimize shipping costs.

We maintain a less than 1% breakage rate. All ceramic toilets are packed in 5-ply reinforced honeycomb cartons and secured on plywood pallets. We offer a "Free Replacement Policy" for any verified transit damage.

Yes. Our factory is ISO 9001 certified. Our products hold full certifications for global markets, including cUPC & WaterSense (USA/Canada), CE EN997 (Europe), WaterMark (Australia), and SASO (Saudi Arabia).

Yes. We can ship a sample unit via air freight (DHL/FedEx) within 7 days. This allows your engineering team to physically verify the flush performance, rough-in dimensions, and glaze quality before mass production.

We provide a 10-Year Warranty on the ceramic body (against glazing defects or cracking) and a 3-Year Warranty on flushing mechanisms (Geberit/R&T valves) and soft-close seat covers.