I’ve handled 4,000+ bathtubs shipped to Australia over eight years. The same problem keeps appearing. Beautiful bathtubs leave factories perfect, then arrive in Sydney or Melbourne damaged. Site managers call me saying another batch is ruined.

This is not bad luck—it’s a structural problem. With rising port congestion, tighter schedules, and higher labor costs, one damaged batch stops work across floors, leaving workers idle and costs mounting. Better packaging plus smarter freight strategy solves this.

Three years ago in Brisbane, a developer ordered 287 bathtubs. Nineteen arrived cracked. This is a typical case, not an extreme one. The handover delayed six days, costing more than the bathtubs themselves. The developer asked: “How do we prevent this?” This article shows you how.

Table of Contents

Why Do Damaged Bathtubs Cause Cost Blowouts in Hotel Projects?

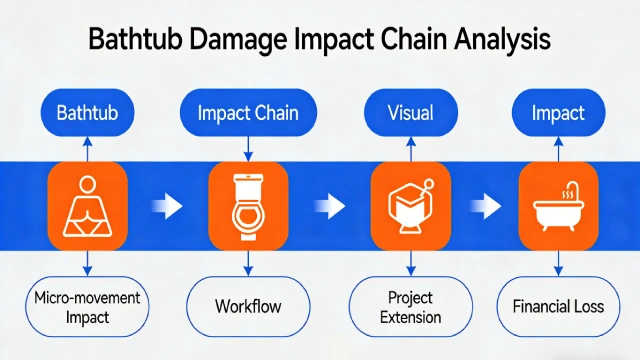

Every damaged bathtub creates a clear impact chain: micro impact → workflow disruption → compound delays → hotel-level financial loss.

A single damaged bathtub delays entire floors from inspection, affecting 10-20 subcontractors and costing $500-2,000 daily. Re-ordering from overseas takes 4-8 weeks, potentially delaying hotel opening and losing $24,000+ in daily revenue for 200-room properties.

How does one damaged bathtub cascade into project-wide delays?

The sequence is brutal: 1 cracked tub → failed inspection → 15 subcontractors rescheduled → 3-week delay. I saw this in Perth with a 180-room hotel. Floor 3 was inspection-ready except room 312—its bathtub arrived cracked. The replacement took 23 days from overseas. This pushed hotel opening back three weeks.

Here is a conservative breakdown of the financial impact per damaged bathtub based on real Australian hotel projects:

Cost Impact of Damaged or Delayed Bathtub Installations

| Cost Category | Impact | Estimated Cost (AUD) |

|---|---|---|

| Room downtime | Lost revenue for 4-star hotel | $180–350/night × delay days |

| Labor rework | Remove + reinstall | $800–1,500 |

| Contractor penalties | Rescheduling + idle time | $2,000–5,000 |

| Expedited shipping | Air freight replacement | $600–1,200 per unit |

| Total per damaged unit | Excluding opening delay | $4,580–10,050 |

This excludes reputational damage or financing impact of delayed openings.

Why Does Australia Require 30-50% Stronger Packaging Than Other Markets?

Australia-bound shipments face 20-40 day sea freight, frequent transshipment through Singapore or Hong Kong, container rain from equatorial crossing, and aggressive port handling. (Source: DTFU Logistics — Shipping Guide Nov 2025)

This requires 30-50% stronger packaging than European or North American routes. General export packaging ≠ Australian-optimized packaging. Australia = longer distance + more handling points + harsher climate.

What makes the Australia-bound supply chain especially high-risk?

A typical journey has seven handling points over 35-45 days versus European shipments with 3-4 handling points over 12-15 days. I visited Shanghai port last year. Forklift drivers load 200 containers daily. Speed matters more than care. Your bathtub is just another box. (Source: Waytron Logistics Guide)

These are the environmental and handling challenges that make Australian shipments uniquely demanding:

Logistics Challenges Affecting Bathtub Quality

| Challenge Factor | Impact on Bathtubs | Mitigation Required |

|---|---|---|

| Container temperature cycling | 60°C day to 15°C night causes condensation | Industrial desiccants + vacuum bags |

| Container rain | Water stains on composite stone | Multi-layer moisture barriers |

| Ocean vibration | 20–40 days stresses thin walls | Custom internal supports at 4+ points |

Composite stone is particularly vulnerable. Its porous surface absorbs moisture, causing discoloration. Vibration causes micro-fractures that expand during temperature cycling. One supplier had 12% damage on Australia shipments versus 2% to Europe. We redesigned for Australian conditions. Damage dropped to 1.3%.

Why does the last mile cause 40-60% of all bathtub damage?

Industry data shows 40-60% of all bathtub damage occurs in the last mile. Melbourne and Sydney ports experience congestion. Containers sit 3-7 days, moved multiple times. Each movement risks damage.

Construction sites are chaotic. Site workers are skilled tradespeople—not trained handlers. Concrete, sharp edges, and debris create scratch and impact hazards. I watched a Gold Coast team drag crates across concrete. Twelve bathtubs got scratched underneath. Eight-day delay cost approximately $31,000.

The Four Packaging Failures That Cause 80% of Bathtub Damage

Top four pain points: (1) unclear or inconsistent packaging specifications between batches, (2) pallet designs causing weight imbalance and stress concentration, (3) lack of drop/shock testing data, and (4) zero visibility during freight.

Failure 1: Why do unclear specifications lead to damage?

First batch used 12mm plywood with foam blocks. Second batch used 9mm plywood with bubble wrap because 12mm was out of stock. The supplier changed materials without notice. The supplier thought “close enough.” It wasn’t.

Every packaging specification must document these critical elements to prevent quality variations:

Packaging Specifications for Damage-Free Bathtub Delivery

| Specification Element | Why It Matters | Minimum Standard |

|---|---|---|

| Crate wood thickness | Impact resistance | 9–12 mm marine-grade plywood |

| Internal support points | Prevents stress concentration | 4–6 custom foam contact points |

| Moisture barrier | Protects against container rain | Multi-layer vacuum-sealed bags |

| Testing certification | Validates protection | ISTA 3A or equivalent |

Missing any single item increases damage probability significantly.

Failure 2: How does poor pallet design create stress points?

Bathtubs are long, hollow shells. A 1700mm bathtub might have walls only 6mm thick. Pressure on wrong points leads to flexing and cracking. Poor pallets concentrate weight on small areas instead of distributing it properly. Rim, base, and corners are the highest-risk impact zones.

Failure 3: Why is absence of testing data a critical risk?

Testing is not a cost—it is verification. ISTA testing simulates drops, vibration, and compression similar to real freight events. An Adelaide project made ISTA 3A testing mandatory. First test failed. The crate corner split during drop test. The supplier redesigned and retested. It passed. Zero damage across 240 bathtubs. The $800 testing prevented at least $20,000 in damage claims.

Failure 4: How does lack of visibility create disputes?

Site teams sign delivery receipts noting “external damage to 3 crates.” They don’t open crates immediately. Two weeks later, they find internal damage. The supplier asks: “How do we know your team didn’t cause this?” Sensors prevent disputes by recording exactly when and where impacts occurred.

What Engineering Solutions Actually Prevent Damage in Australian Conditions?

Effective prevention requires: (1) custom engineered crates with 6-point load-bearing frames, (2) Australian-optimized pallets with 4-directional forklift access, (3) complete specification sheets, and (4) pre-shipment ISTA testing certification.

How do engineered crates with shock-absorbing structures reduce damage?

Double-strength crates use 9-12mm marine-grade plywood versus standard 6-8mm. When forklifts hit the crate, thicker walls absorb shock instead of transferring it inside.

Why 6-point support matters: bathtubs are hollow shells. Point pressure causes flexing. The bathtub contacts the crate at six strategic locations: four base corners and two rim points. Each contact uses custom-molded EVA or PE foam (15-25mm thick, 40-60 density) matching the bathtub’s exact curve.

These are the core components that distinguish Australian-grade packaging from standard export crates:

Why Engineered Packaging Prevents Bathtub Damage

Double-strength crates use 9–12 mm marine-grade plywood instead of standard 6–8 mm.

When forklifts impact the crate, the thicker walls absorb shock rather than transferring force to the bathtub.

6-point support protects hollow bathtub shells from flexing. Strategic contact points—four corners at the base and two rim points—use custom-shaped EVA/PE foam (15–25 mm thickness, 40–60 density) that matches the bathtub’s curvature.

These components are what distinguish Australian-grade packaging from standard export crates:

| Component | Australian-Grade Specification |

|---|---|

| Plywood Thickness | 9–12 mm marine-grade vs standard 6–8 mm |

| Shock Absorption | Reinforced crate walls reduce forklift impact transfer |

| Support Points | 6-point engineered support (4 base + 2 rim) |

| Foam Material | Custom-molded EVA/PE foam, 15–25 mm, density 40–60 |

| Curve Matching | Foam contour aligns with bathtub shape to prevent flex stress |

One supplier redesigned crates. New crates cost $55 more per unit. Damage rates dropped from 8% to under 1%. Better packaging paid for itself within two shipments.

What Freight Strategies Cut Damage Risk by 70%?

Damage-free strategy requires: (1) routing with minimum handling points, (2) shock sensors providing evidence for claims, (3) pre-arrival communication, and (4) White-Glove delivery for high-value projects.

How do routes with minimum handling points reduce damage?

Fewer handling points = fewer forklifts = fewer risks. One supplier’s European shipments averaged 3.2 handling points. Australian shipments averaged 6.8 points. European damage rates: 1.8%. Australian rates: 7.3%. Direct sailings eliminate transshipment. Faster is not safer when it means more handling points.

Based on data from 2,400+ bathtub shipments over three years, here’s the correlation between route complexity and damage rates:

Shipping Route Risk Comparison

| Route Type | Handling Points | Transit Time | Damage Risk |

|---|---|---|---|

| Direct sailing | 4–5 | 25–30 days | Low (2–3%) |

| Transshipment via Singapore | 6–7 | 22–27 days | Medium (5–7%) |

How do shock sensors clarify responsibility?

Sensors attach to crates recording all significant events during transit. Data downloads showing exactly when and where excessive impacts occurred. Sensors also prevent disputes between carriers and suppliers by providing objective evidence. On a Brisbane project, we equipped 120 crates with $28 sensors. Five crates registered impacts above 18G threshold. Four had damage. Insurance claims processed within 10 days versus typical 30-60 day disputed claims.

How Can Your Supplier Reduce Risk Through Better Systems?

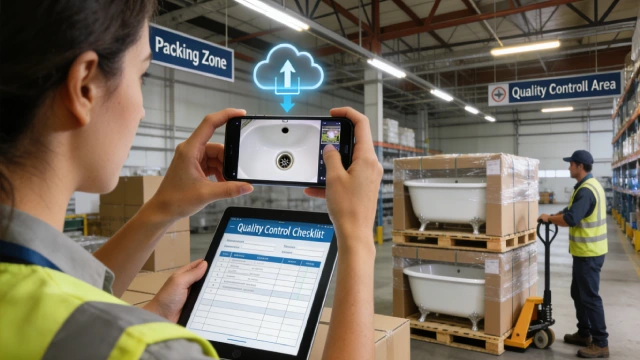

Risk-reducing capabilities include: (1) standardized packaging across batches, (2) real-time QC documentation with photos, and (3) packaging specifically engineered for Australian conditions.

Why does standardized packaging prevent inconsistencies?

Professional suppliers maintain documented procedures with photos. Always ask suppliers to show their packaging SOP with photos. One Guangdong supplier created a 22-page packaging manual. Within six months, client complaints dropped 78%.

How do real-time photos build buyer confidence?

Modern suppliers use smartphones for real-time documentation. Photos upload immediately to shared client systems. Real-time documentation builds trust and reduces disputes.

Here’s the minimum documentation standard that professional suppliers should provide at each stage:

Packaging Documentation Checklist

| Document Type | Contents | When Provided |

|---|---|---|

| Progress photos | 6–8 photos per crate showing key stages | During packing |

| Material verification | Wood thickness, foam density, bag specs | Before packing starts |

| ISPM 15 certification | Photos of stamps + treatment certificates | After crate completion |

I worked with a skeptical client using a new supplier. The supplier offered comprehensive real-time documentation. Within three days, the client could see photos of their bathtubs being packed. This visibility built confidence.

Conclusion

Clients don’t buy crates—they buy project certainty. Every dollar spent on proper packaging prevents tens or hundreds in damage-related losses.

Smart packaging and freight strategy reduces damage from 5-8% to under 1%, prevents delays worth $500-2,000 daily, and protects hotel opening schedules generating $24,000+ daily revenue for 200-room properties.

If you want packaging engineered specifically for Australian conditions, we can provide a customised design proposal and show real examples used in 4-5 star hotel projects across Australia. Reach out and we can review your current packaging and freight plan and identify hidden risks within 24 hours.

For a comprehensive guide on avoiding costly bathtub problems before construction even begins, check out our full article here.

One-Stop Bathroom Solutions for Commercial Projects

We provide integrated one-stop bathroom solutions for hotel and commercial projects, supporting coordinated specifications and project execution.

▼ Submit the form below to connect with our team and explore project cooperation. ▼